| Prod Model: |

XB-OTS-1000M |

| Maxcapacity: |

<1000kn |

| Accuracy Grade: |

0.5 |

| Load Way: |

Electronic Load |

| Loading Method: |

Dynamic Load |

| Cooling Rate: |

0.7c~1.0c/Min (Average) |

| Temp Fluctuation: |

+/-0.5% |

| Weight: |

100-500kg |

| Power Source: |

AC380V |

| Pressure Range: |

101kpa ~1kpa |

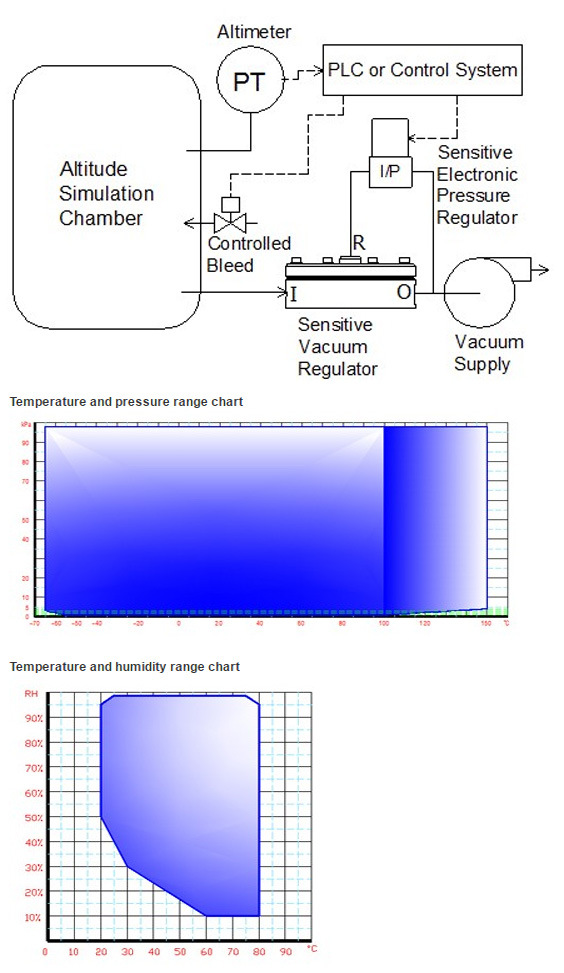

| Temp Range: |

-70c~+150c |

Product Description

Temperature and Climate Low Air Pressure Altitude Simulation Cabinet Test Chamber

Description :

High Altitude Simulation Test Chambers are used in different industries like the instruments and meters, electrical products, materials, spare parts, equipment, etc, but mainly in aviation, aerospace, information, electronics and other industries. This machine can be operated at a low pressure, high temperature, low temperature, under the effect of single factor or multiple conditions at the same time. Simulation of high-altitude conditions like might be found in mountainous regions. Test for electric performance parameters of the specimen.

Quick Details:- Place of Origin: Guangdong, China (Mainland)

- Brand Name: OTS

- Power: Electronic

- Usage: Process Testing Machine

- Temp range: -70ºC~+150ºC

- Standard: CE, IEC, MIL

- Warranty: 1 Year

- Power supply: AC 3 Phase 380V 60/50Hz

- Application: Lab

- Material: Stainless Steel

- Controller: LCD Touch Screen Controller

- Cooling Mode: Water cooled

Specification :| Model | XB-OTS-252M | XB-OTS-504M | XB-OTS-1000M | XB-OTS-2160M |

| Inner Size (D*W*H)mm | 600*600*700 | 800*700*900 | 1000*1000*1000 | 1200*1400*1200 |

| Capacity(KW) | 11 | 15 | 16 | 18 |

| Chamber Volume(L) | 252 | 504 | 1000 | 2160 |

Specifications | Temp range | -70ºC~+150ºC | -70ºC~+150ºC | -70ºC~+150ºC | -70ºC~+150ºC |

| Temp fluctuation | ±0.5% |

| Temp deviation | ≥100ºC, ±3.0ºC(at 101kPa, ATM no load) |

| <100ºC, ±2.0ºC(at 101kPa, ATM no load) |

| Cooling rate | 0.7ºC~1.0ºC/min (Average) |

| Pressure range | 101kPa ~1kPa |

| Pressure accuracy | ±2kPa (101kPa ~ 40kPa), ±0.5kPa (4kPa~40pKa ), ±0.1kPa (4kPa~1kPa) |

| Depressurization rate | 101kPa ~1kPa≤30mins (Room temp) |

| Pressure recovery rate | 10kPa/Min(adjustable) |

| Material | External chamber | Cold-rolled steel sheet(Rust proof&Plastic Spray treated)/Stainless Steel plate |

| Internal chamber | Stainless steel(SUS304) |

| Pressurized parts | High quality steel plate(Rust proof & Plastic spray treated) |

| Insulation material | High quality glass wool |

Cooling

System | Compressor | Semi-Hermetic Compressor |

| Cooling way | Water cooled |

| Temp regulating method | Balanced Temperature & Humidity Control System (BTHC) |

| Pump | Rotary vane type vacuum pump |

| Heater | Iron-chrome wire heater |

| Sight window | Circular viewing glass incorporating heat generator |

| Temp Sensor | Pt-100 |

| Controller | Touch Screen Controller |

| Safety Devices | Over pressure, heat and current protection compressor, over temp. protection, over load protection for blower, hydraulic and water lack Protection, leakage protection, phase-lack protection, Pump failure alarm |

| Standard Accessory | Viewing window, Cable Port( 1 located on the left side), Baffle, Baffle frame*2 |

| Power | AC380V/50Hz, 3Phase 4 wires+ Ground Wire. |

| Note: 1. We reserve the right to change specifications without prior notice 2. Customized sizes and configurations are available |

2. Altitude: ground to 100,000 feet

3.External pressure type box body structure and stainless steel tank design, rational air circulation system and scientific layout of heating, refrigerating system.

4.Adopts international brand of imported parts for cooling system to improve operation reliability

5. High precision and stable performance with touch screen controller, friendly Man-Machine interface.

6. Multiple layers of safe device , easy for maintenance.

7.Viewing window and cable ports are available.

8. Vacuum pump sized for climb/dive rate required by application

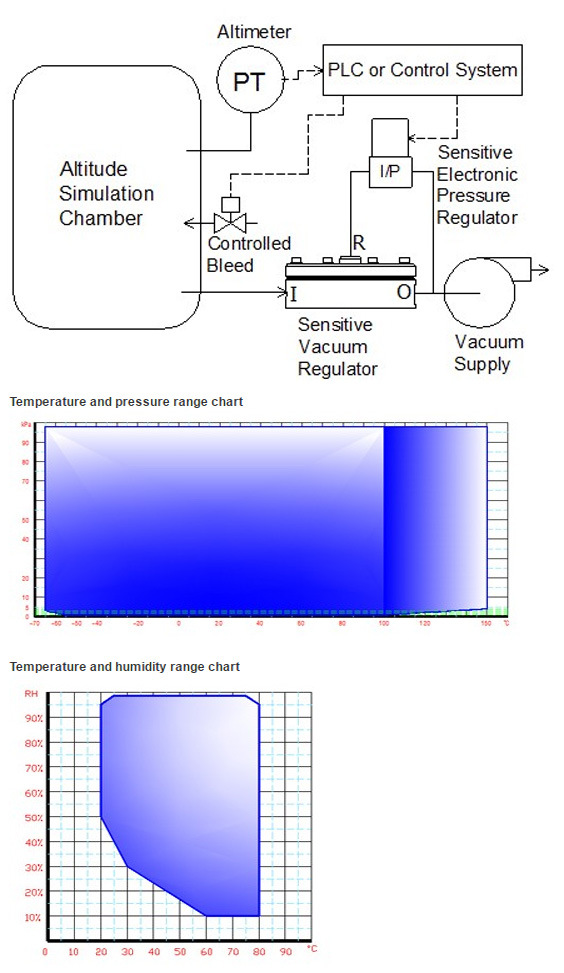

Altitude chamber working principle:

Certificate:

Global safety design, use our chambers safely and with peace of mind for many years to come.

We deliver chambers that conform to international safety standards.

Our chambers conform to ISO risk assessment as well as global safety design electrical safety standards such as CE marking and EMC directive.

Packing & Shipping

Packaging Details:Strong wooden case

Delivery Detail: 3 months after getting the payment

Our Services:

We are here to help you. Services available:

Replacement manuals

- Consumables and replacement parts

- On-site maintenance and repair

- Warranty support

- Over-the-phone service support and advice

If you have an OTS chamber , we will do our best to help you in whatever way we can.

Manuals: PDF files of manuals for current models are available free. Please contact us to request a copy. Older and printed copies at additional charge.

- Service repair: We prefer you contact us direct at the factory with any problems you may be experiencing. We help diagnose the problem, arrange for any needed parts, and schedule a technician to do the repairs. Rarely can a local contractor get all that done for you as quickly as we can. We also guarantee the work .

Our Company

OTS (Overall Testing System)

Was established in 1978, with 35 years' history

With 30,000 square meter salable production base and 120 employees

Is one of the leading companies solely dedicated to manufacture of

Environmental Simulation Test Chambers ,Physical Testing Equipment .

(such as constant temperature and humidity chambers, environmental chambers, climatic test chambers, rain and dust test chambers,thermal shock test chambers,fast change rate chambers, salt spray chamber,UV test chambers,walk in test chambers and other special customized test chambers ; tensile testing machine, vibration test machine ,carton compression testing machines, bursting strength testing machine etc.) ..

OTS has the equipment and expertise, with own R&D and consultant team, to meet and exceed your testing requirement. with offices in unrivaled quality advantage, dynamic management team with superb manufacturing process,also the quality with the world norms: ISO , ASTM, DIN, EN, GB, BS, JIS, ANSI, UL,CE, TAPPI, AATCC, IEC, VDE...

FAQ:

Q1 : Can you customize the product?

A: Yes, we can customize any products according to requirements.

Q2 : How to choose the most suitable products?

A: Our professional team will give you the best suggestion,just be patiently to tell us the information about the parameters your required.

Q3 : Can you arrange installations and commissioning in our lab?

A: Firstly, for standard chamber we had 3-5 days commissioning before shipping , you just need link power in your lab, then can start to operate

Secondly; we had detailed operation manual with chamber , any problems you can find and solve in it

Thirdly, some of customized chambers we should to install and teach your team to operate .

If you want to know more information...

Please leave a message below and click " SEND "

Thanks for your time and attention~Thank you!

Dongguan Xin Bao Instrument Co., Ltd with owner brand of OTS has been dedicating in providing professional testing equipment with top quality since its establishment in 1978, It owns sophisticated and advanced technology in producing temperature and humidity chambers, climatic test chambers, environmental chambers, thermal shock test chambers, rain and dust test chambers, salt spray chambers, walk in /drive in test chambers and other customized test chambers, tensile testing machine, vibration test machine, Paper Packaging Testing Equipment, Luggage Testing Equipment, Furniture Testing Equipment, Leather and Shoes Testing Equipment, Mobile phone and PC Testing Equipment, Battery Testing Equipment, Plastic and Rubber Testing Equipment, Products made by OTS reach international standards: ISO, ASTM, DIN, EN, GB, BS, JIS, AMSI, UL, TAPPI, AATCC, IEC. They are also widely used in different area: R&D Institutions, Quality Inspection Institutions, Universities, electronics, communications, instrumentation, automobile, plastic, metal, Building materials, Aviation, etc.

Now our company has two main production bases over 3 0, 0 0 0m² Each in Taiwan and Dongguan, a branch company in Suzhou and offices in South Asia, Europe, USA. OTS has an independent laboratory which exhibits all of our currently produced machines, so customers can check the function and quality in one-time. What's more, OTS has many finished equipment in stock so that we can delivery products to you urgently. Every machine produced by OTS must be examined before shipment and with lifetime maintenance service.

With the exquisite manufacturing process, an innovative development and research team, a professional sales team and excellent after-sale service, OTS is ready to take part into international market and set an example in this field.