| Prod Model: |

GHCC -65 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Belt Width: |

650mm (25in) |

| Usage: |

to Reduce Material Shock to Belt |

| Application: |

Coal Mining Industry, Cement Plant, Power Plant |

| Material Of Impact Bar: |

Made of UHMWPE and Rubber by Heat Vulcanization |

| Elongation Of Impact Bar: |

>400% |

| Hardness Of Impact Bar: |

45-55 Shore a |

| Material Of Frame: |

High Strenghth Metal Frame |

| Fire Resistant: |

Yes |

| Certification: |

ISO, CE, SGS, Ohsas |

| Applied Standard: |

ISO, CE, DIN, Cema, JIS, GB |

Product Description

One,Product introduction

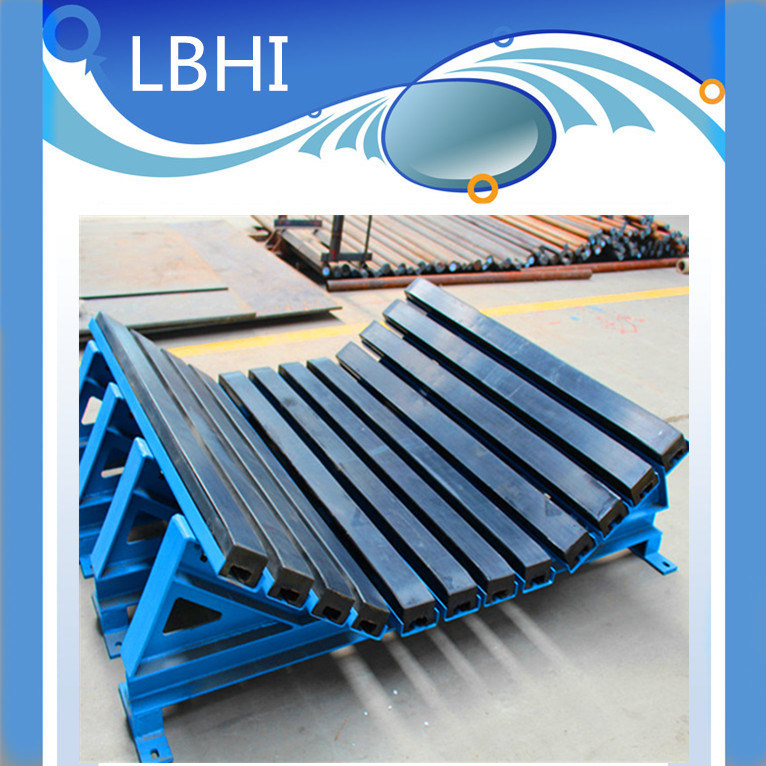

Conveyor impact bed is used for the loading section of belt conveyor, has better buffering effect than traditional impact rollers.The product can support and protect the belt, preventing the falling material damage the belt.

Two,Technical advantage

1,With impact bed, material overflow and belt off-track can be avoided effectively;

2,Impact beds can provide all-sided support and excellent impact effect for loading section;

3,Smooth UHMWPE surface minimize the friction between belt and impact bar;

4,The front end and back end of impact bars are cambered, which guarantee that the belt passes the impact bars smoothly;

5, The impact bars are made of UHMWPE and rubber by heat vulcanization, which can absorb the impact of falling material;

6,High-strength metal frame is stable and easy to install;

7,Do-it-yourself replacement of individual impact bar, which only takes a few minutes.

Three,Technical parameter

| Type | Belt width

(mm) | L1

(mm) | L2

(mm) | Q

(mm) | H

(mm) | θ | L=1500mm | L=1200mm |

d(mm) |

| M(mm) | n | M(mm) | n |

| GHCC-50 | 500 | 740 | 800 | 130 | 220 | 35°/45° | 375 | 3 | 350 | 3 | 14 |

| GHCC-65 | 650 | 890 | 950 | 130 | 235 | 35°/45° | 375 | 3 | 350 | 3 | 14 |

| GHCC-80 | 800 | 1090 | 1150 | 170 | 245/270 | 35°/45° | 375 | 3 | 350 | 3 | 14 |

| GHCC-100 | 1000 | 1290 | 1350 | 200 | 300/325 | 35°/45° | 375 | 3 | 350 | 3 | 18 |

| GHCC-120 | 1200 | 1540 | 1600 | 220 | 335/360/390 | 35°/45° | 375 | 3 | 350 | 3 | 18 |

| GHCC-140 | 1400 | 1740 | 1800 | 240 | 350/380/410 | 35°/45° | 375 | 3 | 350 | 3 | 18 |

| GHCC-160 | 1600 | 1990 | 2060 | 240 | 405/450 | 35°/45° | 375 | 3 | 350 | 3 | 18 |

| GHCC-180 | 1800 | 2210 | 2280 | 240 | 435/480/520 | 35°/45° | 375 | 3 | 350 | 3 | 18 |

| GHCC-200 | 2000 | 2400 | 2470 | 240 | 455/495/540 | 35°/45° | 375 | 3 | 350 | 3 | 18 |

| GHCC-220 | 2200 | 2720 | 2800 | 240 | 520/560 | 35°/45° | 375 | 3 | 350 | 3 | 18 |

Four,Package,Freight &Payments

Package | We all take standard export packing cases made of exemption plates that thickness of the composite plates are about the 9mm to 15mm according with the export requirements.Of course,We also can take the wooden cases made of solid wood with fumigation and supply the Inspection Certificate of Fumigation.

|

Freight | (1)Shipping:We cooperate with good international ship agency to ensure the interests of the buyer that the buyer can receive the goods in time.We usually accept liner shipping so that we should contact duly and co-operate on the freight peak to solve those problems of transportation.If you have any other requirements,Please tell us and consult with it.

(2)Express and Air transport:We also move goods by express and air transport if you really have emergency demand for these goods .But we can't take the resulting costs and the scale of the goods must be small.

(3)International multimodal transport:The qualified MTO takes the transportation of the goods to make sure to arrive in terminal on time.We use container transport in general with the exception of special circumstances.

|

Payments | 1.30%T/T deposit +70% sight, confirmed and irrevocable L/C

2.100% sight, confirmed and irrevocable letter of credit

3.30%T/T +70% after seeing Ocean copy or fax of Bill of Lading

4.Other trusted platform for third-party to pay

5.Other circumstances |

Five, Company Introduction

LIBO HEAVY INDUSTRY SCIENCE&TECHNOLOGY CO.,Ltd. is specialized in design and manufacture of belt conveyor and key components, such as rollers, pulleys,disc brake, transmission drive, take-UPS, belt cleaner, impact bed, coupling and so on. our products have been widely applied in coal mine, power station, cement plant, iron mine and wharf.

1,Advanced Manufacture line

We own complete manufacture lines, including the cutting of all parts, rough and elaborate processing, fitting-up and whole-set assembly.

2,Technical strength

There are more than 800 employees in total, including 244 engineers. Among these technical staff, 109 R&D personnel for engineering departments, 66 sales engineers for sales department and 69 welding engineers, Equipment engineers,Process engineers and QC engineers for producing department.

Six, The LBHI Advantage

LBHI offers a wide range of state-of-the-art technology for all applications of Bulk Material Handling.We have more than 240 emplyees engaged at project management and R&D.We have executed and delivered the material handling system for more than 60 projects worldwide in the past 10 years.

1,First Class Product

LBHI offers integrated and optimal solutions that are designed and fabricated inhouse;

2,First Class Manufacturing

LBHI has advanced facilities and international standard process management,to ensure the same,consistent high level of quality.

3,First Class Service&Expertise

LBHI has more than 20 service partners around Asian countries.We have the expertise and resources to meet different requirements from the customers.

Contact Us

LIBO Heavy Industries Science&Technology CO.,LTD.

Contact person:Cathy Wong

Telephone:+86 538 6925885

Address:Ningyang Economic Development Zone,Shandong P.R.,China

LIBO Heavy Industries Science & Technology Co., Ltd. Short for "LBHI" or "LIBO"

LIBO is located at the foot of Mount Tai, it is a professional R&D and manufacture enterprise of China national High-tech Enterprise in bulk material handling equipments and their key components, especially belt conveyors and round stockyards stacker-reclaimers, registered capital of 119.6 million yuan, It is one of the largest bulk material handling equipments enterprise for its large scale, advanced manufacture facilities complete product chain and comprehensive strength.

LIBO Currently has the following four sunsidiaries:

LIBO Heavy Machine Technology Co., Ltd. Ningyang Branch

Chengdu LIBO

LIBO international Mechanical Engineering

Guizhou LIBO

Brief Advantages of LIBO / LBHI

1. Above 10 years experience in mining machinery manufacturing

2. Well equipped with complete facilities, more than 300 rich experienced

Engineers and more than 500 skilled employees

3. Highly advanced digital processing equipment.

Manufacture belt conveyor:

Belt conveyor

Coal handling belt conveyor

Long distance curved belt conveyor

Large-angle upward belt conveyor

Downward belt conveyor

Large Inclination Downward Belt Conveyor

Long-distance Curved Belt Conveyor

Pipe Belt Conveyor

Coal mine belt conveyor

Material handling system

Two way belt conveyor

Manufacture belt conveyor

Manufacture products:

Roller, idler

Pulley

Coupling

Winch

Taper-lock

Impact bed

Unloaded

Hydraulic soft start device

Self-cooled disc controllable braking device

Hydraulic tension device, Take-up device

Mining explosion-proof and intrinsically safe programmable control box

Mining intrinsically safe operating bed

Mining explosion-proof AC frequency converter

Integral type belt catcher/ broken belt protector

Steel structural handling system

Mining explosion-proof AC frequency converter

Integral type belt catcher, broken belt protector