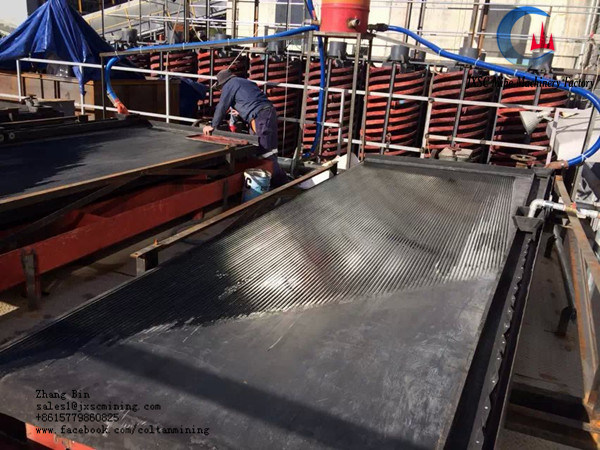

Tin Shaking Table for Tin Ore Concentrating Project

| Price: |

US $ 1550-2450/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Set |

| Pay Type: |

T/T |

| Prod Model: |

6S |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Capcity: |

0.5-2 Tons/Hour |

| Water Required: |

3-5 T/Hour |

| Feeding Size: |

0.075-2 Mm |

| Type: |

Gravity Separator |

| Voltage: |

380V |

| Weight: |

<1T |

| Certification: |

CE |

| Warranty: |

1 Year |

| Color: |

Black |

| Customized: |

Non-Customized |

| Condition: |

New |

| Material: |

Glass Fibric Reinforce Plastic |

Product Description

Detailed description

Shaking table is one of the major gravity ore dressing machines, in some aspect it is the most important gravity ore dressing machine. It was designed to concentrate the fine-grinded or micro-grinded rare metal & precious material.

The shaking table separate the mineral granular based on the gravity differences between the different materials inside the pulp. When the pulp reached the table surface from the feeding channel, the granular in it will be effected by the gravity force, water flow force, the inertial force and friction force which comes from the reciprocating movement of the table surface, under the effect of these four forces, the granular inside the pulp will be classified and moved to the different direction: the high density one will go front and drop from the concentration end, the gangue will go to the tailing side, and the middles will be re-concentrated on the shaking table.

Application

Shaking table has been widely used in the rare metal dressing plant, such as scheelite, wolfram, tin ore, tin ore, placer mine, tantalite, columbite and etc. And also some times it been used to concentrating manganese ore and iron ore.

The shaking table normally had been put at the end of ore dressing plant as the final concentration process.

Technical Specification

Name |

Specification |

Technical Data of Gravity Separator Table |

Bed Dimension |

4436× 1825× 1536m/m |

Bed Type |

Stroke(m/m) |

Stroke Per Minute

(r/m) |

Water Consumption(M3/Set Day) |

Process Capacity(T/Set Day) |

Outline Dimension |

5454× 1825× 1242m/m |

Adjustable Stroke |

8-22m/m |

Coarse Sand Bed |

16-22 |

240-290 |

190 |

30 |

Fitted Motor |

JO2-31-61.5 kw |

Fine Sand Bed |

10-16 |

300-320 |

80 |

8 |

Weight |

1012 kilo |

Carved Groove Bed |

10-16 |

330-340 |

50 |

8 |

Deck Data

Bed Type | Separating Technical Conditions |

Feed Ore Size

(m/m) | Feed Ore Density

(%) | Feed Ore Volume

(M3 /Set Day) | Water Consumption

(M3/Set Day) | The Minimum

Slope |

| Coarse Sand Bed | 2-0.2 | 20-25 | 130± | 60 | 2° 30 |

| Fine Sand Bed | 0.5-0.037 | 15-20 | 50± | 30 | 1° 50 |

Carved Groove

Bed | 0.074-0.019 | 15-20 | 30± | 20 | 0° 45 |

Jiangxi Province County Mining Machinery Factory is specialized in researching, manufacturing, sales and door tracking service as one of the metallurgical mineral processing machinery enterprise, our company is engaged in the mineral processing equipment product design and production for several years history, has accumulated rich experience in design and production. Enterprise in mineral processing equipment industry has had a positive effect, set up the good reputation. The company constantly with technology innovation, hard to develop the country generation into high technology and new technology processing equipment, make excellent brand, mainly the manufacture of the products like as shaking table, flotation equipment, crushing(powder)equipment, magnetic separation equipment, screening equipment, ore washer classifying equipment, agitation equipment, spiral chute equipment, gravity separation jig, feeding equipment, milling equipment. And we can manufacture various types of mineral processing machinery and equipment according to our customers' requirements. Our products are widely used for sorting gold, silver, copper, iron, tungsten, lead, zinc, tin, molybdenum, nickel, tantalum, niobium, manganese ore, coal, monazite, rutile, diamonds, other precious metals and precious metals mine, and for the flotation colored, black metal, precious metals and other minerals.

Company has won the Outstanding Business Award, and many times as honesty, service and advanced company, is the backbone of the metallurgical industry, mineral processing machinery business. The company has export qualifications, our products sell well all over the world for many years, especially exported to Brazil, India, Indonesia, South Africa, Somalia, Philippines, Malaysia, Sudan, Kazakhstan, Kyrgyzstan, Cambodia, Vietnam, Korea, Mongolia, Myanmar and other countries.