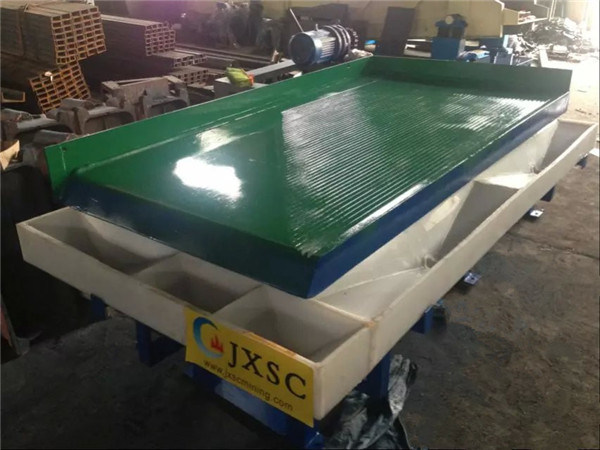

Ore Dressing Table, Tungsten Shaking Table for Sale

| Price: |

US $ 1100/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,Western Union |

| Prod Model: |

6S-4500, LY2100, LY1100 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Models Available: |

6s-4500, Ly2100, Ly1100 |

| Application Field: |

Gold/Ilver/Tungsten Ore/ Tin Ore/Iron/Zircon Separ |

| Max Feed Size: |

0.037mm-2mm |

| Feed Density: |

10%-30% |

| Capacity: |

0.5-1.8t/H |

| Table Material: |

Glass Fibre Reinforced Plastic |

| Table Deck Available: |

Coarse Sand Deck/ Fine Sand Deck/Slime Sand Deck |

| Drive Type: |

Electic Motor Driven and Diesel Engine Driven |

| Installation: |

Provide Setup Video&Work Video&Technical Drawing |

| Certificate: |

CE&TUV&SGS&ISO |

| Type: |

Gravity Separator |

| Voltage: |

380V |

| Weight: |

<1T |

| Certification: |

SGS |

| Warranty: |

1 Year |

| Customized: |

Customized |

| Condition: |

New |

| Material: |

Glass Fiber |

| Material Feature: |

Wear-Resistance |

| Color: |

Customized |

Product Description

Company Introduction:

Jiangxi Shicheng Mine Machinery Factory is a metallurgical mineral processing machinery enterprise which has been specialized in researching, manufacturing, sales and tracking service for many years. The main products are shaking table, flotation cell, crusher, magnetic separator, trommel/vibrating screen, washing scrubber, spiral chute, jig concentrator, feeder, millertect..

Shaking Table: 6-S Shaking Table; Wilfley Table; Concentrator Table

Shaking Table is the main gravity concentrator. It is applicable for the separation of fine-grained, micro-grained rare metal, ferrous and non-ferrous metals, precious metal, coal and other minerals. It can carry out the ore concentration operation independently, also it can work in conjunction with jig, screw separator, centrifugal separator and other equipment.

Shaking Table Operation Principle:

The Shaking Table separation is operated by the force between deck water flow and transverse water flow. The riffles or the grooves in the deck is longitudinal which is vertical with the direction of water. When the water flows, it will cause the swirling. The force caused by water swirling and deck pulsation will loosen the ore sand layer and the different minerals will be separated as the different density. The heavier mineral will fall down, and the lighter one will be raise up. So the concentration is operated.

Shaking Table Classification:

LS glass steel shaking tables are effective gravity separation equipment which can be used for different operation such as rough selection, elaborate selection and scavenging for large, medium and small-sized factories and applies to the sorting of nonferrous metal, ferrous metal, rare and precious metal, gold and nonmetallic ores of fine grains. Such shaking tables are divided into ore sand tables and ore slime tables. Ore sand tables apply to the sorting of coarse ores and ore slime tables apply to the sorting of fine ores.

Shaking table are under transportation:

Name | Unit | Coarse ore Deck | Fine sand

Deck | Slime Deck |

| Deck Size | Length | mm | 4450 | 4450 | 4450 |

| transmission end width | mm | 1855 | 1855 | 1855 |

| Concentrate end width | mm | 1546 | 1546 | 1546 |

| Maximum Feeding Size | mm | 2 | 0.5 | 0.15 |

| Feeding Amount | t/d | 30-60 | 10-20 | 15-25 |

| Feeding Density | % | 25-30 | 20-25 | 15-25 |

| Stroke | mm | 16-22 | 11-16 | 8-16 |

| Frequency | f | 45-48 | 18-53 | 50-57 |

| Water added | t/d | 80-150 | 30-60 | 10-17 |

| Transverse slope of Deck | ° | 2° 30-4° 30 | 1° 30-3° 30 | 1° -2° |

| Longitudinal slope of Deck | ° | 1.4 | 0.92 | ------ |

| Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 |

| Cross-section Shape of Deck |

| rectangular | saw tooth | triangle |

| Motor Power | KW | 1.1 | 1.1 | 1.1 |

| Transmission Mechanism |

| Eccentric linkage |

Jiangxi Province County Mining Machinery Factory is specialized in researching, manufacturing, sales and door tracking service as one of the metallurgical mineral processing machinery enterprise, our company is engaged in the mineral processing equipment product design and production for several years history, has accumulated rich experience in design and production. Enterprise in mineral processing equipment industry has had a positive effect, set up the good reputation. The company constantly with technology innovation, hard to develop the country generation into high technology and new technology processing equipment, make excellent brand, mainly the manufacture of the products like as shaking table, flotation equipment, crushing(powder)equipment, magnetic separation equipment, screening equipment, ore washer classifying equipment, agitation equipment, spiral chute equipment, gravity separation jig, feeding equipment, milling equipment. And we can manufacture various types of mineral processing machinery and equipment according to our customers' requirements. Our products are widely used for sorting gold, silver, copper, iron, tungsten, lead, zinc, tin, molybdenum, nickel, tantalum, niobium, manganese ore, coal, monazite, rutile, diamonds, other precious metals and precious metals mine, and for the flotation colored, black metal, precious metals and other minerals.

Company has won the Outstanding Business Award, and many times as honesty, service and advanced company, is the backbone of the metallurgical industry, mineral processing machinery business. The company has export qualifications, our products sell well all over the world for many years, especially exported to Brazil, India, Indonesia, South Africa, Somalia, Philippines, Malaysia, Sudan, Kazakhstan, Kyrgyzstan, Cambodia, Vietnam, Korea, Mongolia, Myanmar and other countries.