| Prod Model: |

YLF1001C |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Product Name: |

Super Low Profile Lift Table |

| Capacity: |

1000kg |

| Min. Table Height: |

85mm |

| Max. Table Height: |

860mm |

| Table Size: |

1450*1140mm |

| Base Size: |

1325*1047mm |

| Lifting Time: |

25s |

| Power: |

380V/50Hz |

| Net Weight: |

357kg |

| Warranty: |

12 Months |

| Application: |

Building Crane |

| Running Mode: |

Stationary |

| Carrying Capacity: |

1000kg |

| Driven Type: |

Electric |

| Feature: |

Lift Table |

Product Description

Super Low Profile Lift Table

Description:

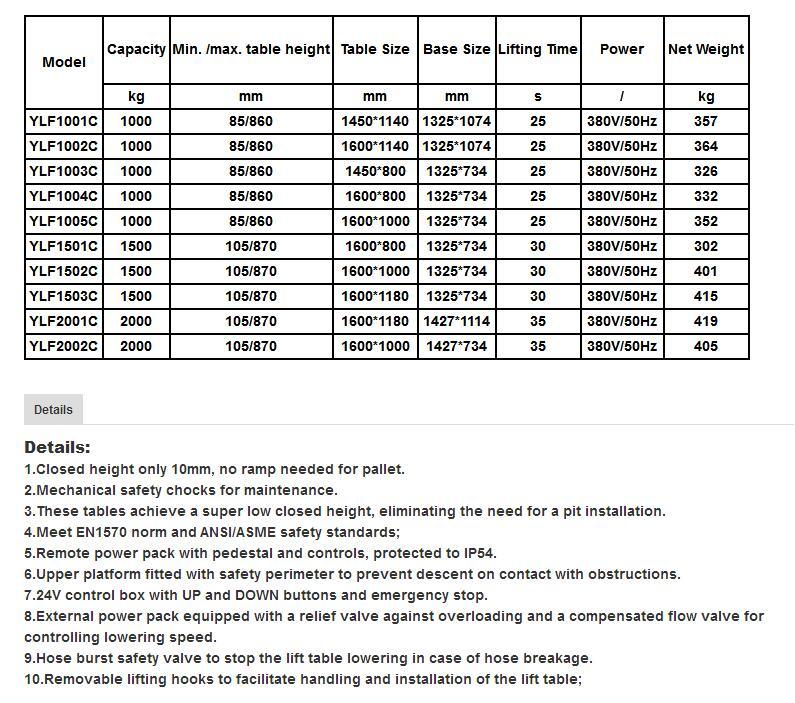

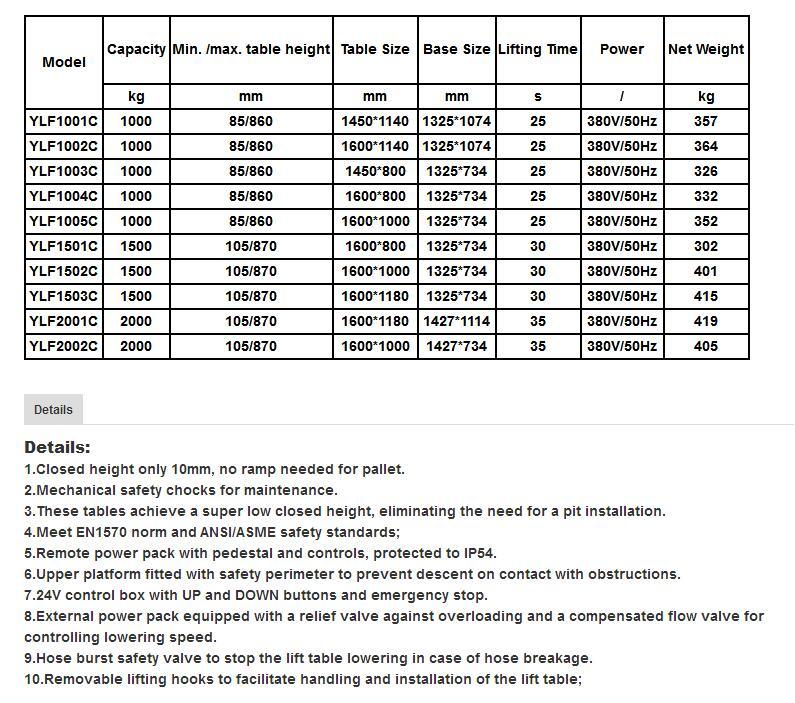

1.Super Low Profile Lift Table, Low Profile Electric Lift Table/Capacity 1.0/1.5/2.0Ton is with superior engineering features rugged dependability.

2.Load and unload skids with a pallet truck without the need for a pit when using the optional approach ramp. 3.Safety features include electric perimeter pinch point guard, emergency stop velocity fuse in cylinders, fused 24V AC hand held control and maintenance supports.

4.Remote power unit comes complete with a plastic cover to protect the motor from dust and debris.

FAQ:

1.Q.Are you factory?

A.Yes.Our factory mainly produce drum handling equipment,drum stacker,drum truck,aluminum hand trolley ,kinds lift table ,forklift attachment and shop crane with CE approved, pasted Third-party certification(SGS/ISO9001).

2.Q.Can I place mix order?

A.Yes.You can mix different models as your request.

3.Q.Can we order products?

A.Yes. Customers can option size,color,weighing,panel etc.Welcome ODM/OEM orders.

4.Q.Can we visit your factory?

A.Welcome anytime .Our factory address:NO.29 Yanjin Road, Yanqiao Industrial Park,Huishan District,Wuxi,Jiangsu,China.You can take the plane, high-speed rail, motor car, train, car.

5.Q.Are the products covered by a warranty?

A.Yes.All our machines carry a full 1 year major parts warranty.

Feactures:

1.Closed height only 10mm, no ramp needed for pallet.

2.Mechanical safety chocks for maintenance.

3.These tables achieve a super low closed height, eliminating the need for a pit installation.

4.Meet EN1570 norm and ANSI/ASME safety standards;

5.Remote power pack with pedestal and controls, protected to IP54.

6.Upper platform fitted with safety perimeter to prevent descent on contact with obstructions.

7.24V control box with UP and DOWN buttons and emergency stop.

8.External power pack equipped with a relief valve against overloading and a compensated flow valve for controlling lowering speed.

9.Hose burst safety valve to stop the lift table lowering in case of hose breakage.

10. Removable lifting hooks to facilitate handling and installation of the lift table;

Competitive Advantage:

1. Heavy duty design with larger platform;

2. These tables achieve a low closed height, eliminating the need for a pit installation;

3. They are manufactured to all European safety standards including EN1570:1999;

4. Remote power pack with pedestal and controls, protected to IP54;

5. Upper platform fitted with safety perimeter to prevent descent on contact with obstructions;

6. 24V control box with UP and DOWN buttons and emergency stop;

7. Hose burst safety valve to stop the lift table lowering in case of hose breakage;

8. Loading ramp is standard equipment.

As a professional manufacturer of material handling and lifting equipment, WUXI TONGYANG MACHINERY TECHNOLOGY Co., Ltd.Is an industry leader in the researching, manufacturing and selling types of drum handlers, stackers, forklift attachments, pallet trucks, platform trucks and lift table.

Since its inception, Wuxi Tongyang Machinery has always paid great attention to maintaining a high level of quality control and process management, thus to ensure full customer satisfaction.We check and load tests each piece of equipment prior to shipping.With the exception of battery connections, most of our equipment is ready to use without assembly when you receive them.

In recent years, our company has introduced a series of advanced equipment including Plastic Spraying machine, CNC cutting machines and Double Hydraulic Pipe Bender.In addition, as an I S O 9 0 0 1:2 0 0 8 certified company;We have already established a long term business relationship with overseas countries and regions.And our equipment is popularly sought after in Europe, America, Australia, Southeast Asia, Russia and many other countries.

We also welcome OEM and ODM orders.We sincerely welcome friends from all over the world to visit our company and cooperate with us on the basis of long-term mutual benefits..

HONOR:

With CE approved, our drum transporter, stackers, pallet trucks and platform trucks are popularly sought after in Europe America, Australia, Southeast Asia, Russia and many other countries.We have already established a long term business relationship with overseas countries.So was certified by ISO9001:2008 and TUV.

Every year get the customers Grade A feedback and happy visit, our factory team will try more best to improve our production, hoping offer more better service for each customer.

Price advantage:Factory directly sale in more competitive price term.

Brand advantage:ODM & OEM (OUR BRAND IS YINGLIFT)

Service advantage:Sales team (10 ), Technical team(4 )and After-sales team(4)

Supply advantage:More than 8 big workshop

Variety advantage:From mechanical equipment to Semi-electric equipment to Full electric equipment.

Manufactured in China

All Wuxi Yinglift material handling products are manufactured in China and we provide an unmatched warranty for all of these equipment.As a professional manufacturer, we are confident in our design, processing, craftsmanship, quality control and performance which enable our material handling equipment to be the leader in this area.

Common Maintenance Replacement Parts

Normally speaking, the quality warranty period of our Yinglift material handling equipment is lasting for one year.However, the following parts are considered common replacement parts and are not covered under this warranty after six (6) months from the date of shipment:Spring plungers;Bearings;Rubber;Hoses;Chains;And Lift Jaws.The following parts are considered common replacement parts and are not covered under this warranty after twelve (12) months from the date of shipment:Wire Rope;Casters;Brakes;Sheaves;Batteries;And Clamping Assembly.

Manufactured in China

.As a professional manufacturer, we are confident in our design, processing, craftsmanship, quality control and performance which enable our material handling equipment to be the leader in this area

Common Maintenance Replacement Parts

Normally speaking, the quality warranty period of our Yinglift material handling equipment is lasting for one year.However, the following parts are considered common replacement parts and are not covered under this warranty after six (6) months from the date of shipment:Spring plungers;Bearings;Rubber;Hoses;Chains;And Lift Jaws.The following parts are considered common replacement parts and are not covered under this warranty after twelve (12) months from the date of shipment:Wire Rope;Casters;Brakes;Sheaves;Batteries;And Clamping Assembly.Welcome customers visit