| Prod Model: |

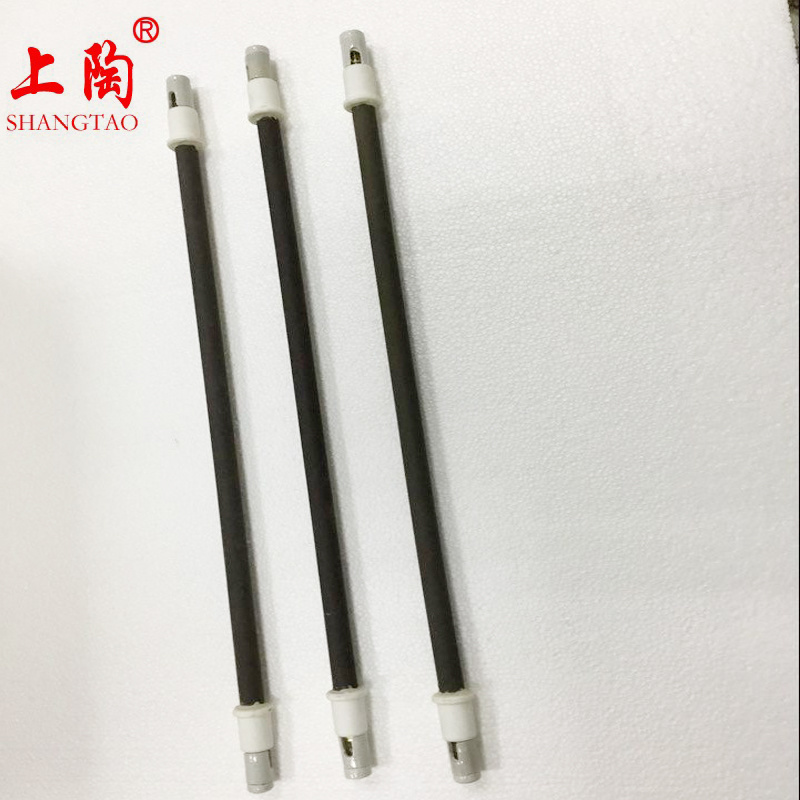

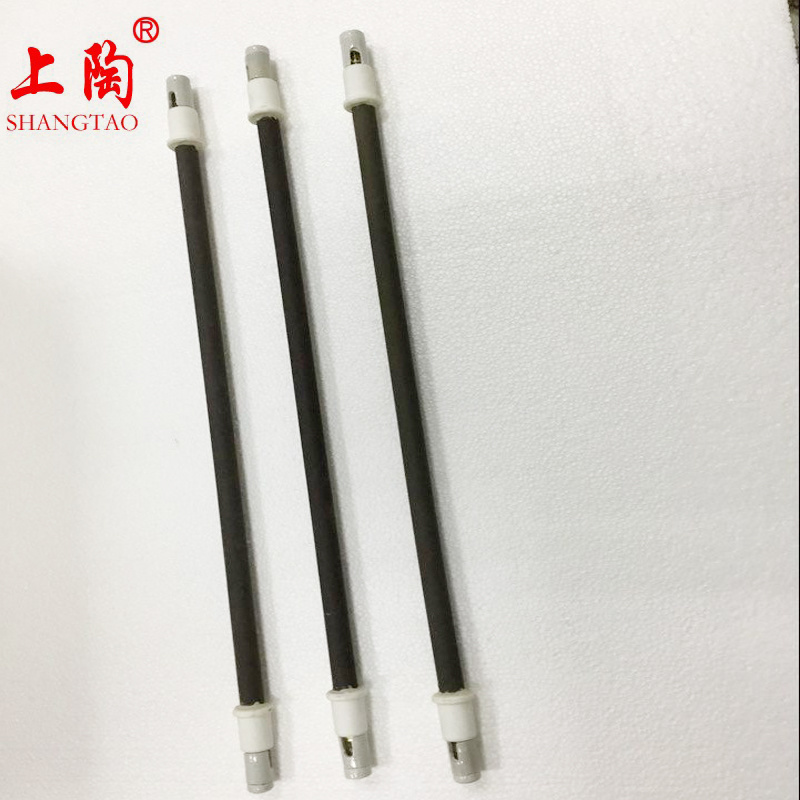

GT-319 |

| Use: |

for Sauna |

| Color: |

Black Body |

| Accessory: |

Metal Reflector |

| Application: |

Heater |

| Structure Material: |

Ceramic |

| Heat Transfer Surface: |

Tubular Heat Exchanger |

| Principle: |

Mixing Heat Exchanger |

Product Description

Introduction of infrared black ceramic heater tube

It is one of most speedy heating elements with most advanced heating and drying technique. At present, we can produce infrared tube with diameter of tube 12mm, 14mm, 17mm, 20mm. The overall length, power and voltage can be customized according to the customers'requirement.

Property of infrared black ceramic heater tube:

This tube is made of carborundum, when connected to electric current, heat energy permeate through the tube, then radiate infrared with wavelength of 3 μ ~ 50 μ ., which the quartz tube, infrared bulb ect can not get.

Purpose:

Dryness: Drying for leather, lumber, metal, plywood, fibre, paint, ceramic glaze, printing, ect.

Baking finish: Car bodywork, motorcycle, bike ect.

Heating: Plastic, PS, ABS molding and induration machining warm-up

Sterilization: Disinfection for food, packing container, bite and sup instrument, medical instrument

Heat preservation/dehumidify

Other use.

Advantage:

Its heat treatment is quicked than common method by 1~10 times, which greatly shorten time of heating up.

Save electric power about 30 %~ 50

Cubage of equipment can reduce more than a half

Naked fire can not produce. High security, wear well.

Maintenance and exchange is easy.

Without dustor or bad gas

Easy operation and autocontrol

Low cost, high efficiency

Dimension (mm) |

Voltage (can be fixed by yourself) |

Diameter of tube |

12(φ) |

14(φ) |

17(φ) |

20(φ) |

316 |

200 |

200 (W) |

300 (W) |

400 (W) |

450 (W) |

416 |

300 |

300 (W) |

450 (W) |

550 (W) |

600 (W) |

516 |

400 |

400 (W) |

600 (W) |

700 (W) |

800 (W) |

616 |

500 |

|

750 (W) |

850 (W) |

1000 (W) |

716 |

600 |

|

850 (W) |

1000 (W) |

1200 (W) |

916 |

800 |

|

1100 (W) |

1300 (W) |

1500 (W) |

1116 |

1000 |

|

|

1700 (W) |

1900 (W) |

1316 |

1200 |

|

|

2000 (W) |

2300 (W) |

1616 |

1500 |

|

|

|

2800 (W) |

1916 |

1800 |

|

|

|

3300 (W) |

Shanghai Gongtao Ceramics Co., Ltd. is one of the most leading and advanced ceramic material companies in China, integrating the design, manufacture and marketing of high-tech ceramics. Brand name "SHANGTAO" was formed more than 20 years ago. We specialize in Alumina products, Zirconia products, Magnesia products, Silicone Nitride products and Alumina Nitride products. We have developed advanced skills and technologies. Our products are widely used in electricity, information, power, automobile and other fields.

Range of Industrial Ceramics: alumina ceramics, zirconia ceramics, titanium oxide ceramics, silicone carbide ceramics, silicon oxide ceramics, special ceramics, high-frequency ceramics, mullite ceramics, general ceramics, refractory ceramics, electronic ceramics, textile ceramics, high purity alumina crucible, electrical ceramics, etc.

SHANGTAO strictly complies with ISO9001 quality management system. Our products are widely used in aerospace, mining machinery, lift, power, paper making, laboratory, nonferrous metal processing, electronics processing, textile machinery and other industries, SHANGTAO provides wholesale and retail services.

We have the largest stocks in Shanghai, professional manufacturing experience, most complete industrial ceramics, rock bottom price, best service, speedy delivery.

Welcome to contact us for cooperation! Also welcome to visit us!