Automatic CNC Glass Cutting Machine Glass Cutting Table for Float Glass

| Price: |

US $ 30000-50000/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,Paypal |

| Max Cutting Speed (M/Min): |

0-200 (Adjustable) |

| Cutting Accuracy (mm/M): |

± 0.20 |

| Glass Cutting Thickness(mm): |

2-25mm |

| Voltage (V): |

220V/380V (Three Phases) |

| Glass Size: |

3660*2440mm |

| Min. Glass Size: |

20*20mm |

| Overall Dimension: |

4500*2900*1500mm |

| Weight: |

4600kg |

| Type: |

Glass Cutting Machine |

| Control System: |

PLC |

Product Description

automatic loading machine (four stations)

1. The machine configuration:1), flip sprocket chain: high precision wear-resisting reinforced;2), transfer roller: import PU material;3), vacuum suction cup: Ding Qing glue material adsorption structure (double);4), flip reducer:Honesty bond (Taiwan).5) Vacuum pump: Joysun (Shanghai)2. Electrical configuration:1), PLC controller:((Taiwan Delta or Japan Mitsubishi));2), frequency converter, Delta (Taiwan);3), touch screen display control, Delta (Taiwan);4), contactor, schneider (France);5), the circuit breaker: schneider (France);6), intermediate relay: schneider (France);7), control transformers: chint (hangzhou);8), main control vacuum electromagnetic valve: the DE guest (Taiwan);9), photoelectric switch, Omron (Japan);10),proximity switch, Omron (Japan);

full automatic glass cutting machine

full automatic glass cutting machine

- Basic instruction and principle

- The equipment that is full automatic double-drive irregular glass cutting machine is mainly used for glass deep-processing, and it is a glass cutting machine we design based on brand-new idea. The equipment we produce bases on advanced technology, such as good servo motors, superior slant racks and cutting optimizer, etc. So it has many characteristics, such as better stability, higher accuracy, faster speed, lower noise, and completer functions, etc.

- Its working principle is, it will be cut glass by the conveyor belt to the workbench, the glass position the positioning of the first machine is good, with a diamond knife wheel cutting head on process control to move along the X axis and Y, respectively, for cutting substrates. Machine control part adopts CNC motion control card, driving part of the application of advanced ac servo motor.

2. The equipment of institutionsAutomatic cutting machine: the chassis mechanism, beams, glass processing desktop, mechanism of the cutting tools, transmission organization, mechanical positioning mechanism, electrical control system.3. The detailed working stepsPlease refer to the automatic cutting machine in detail steps: "automatic glass cutting machine operation instruction handbook".4. Equipment performance1) Using slant racks: this can both improve cutting accuracy and reduce noise efficiently.2) Using round guide whose diameter is 30mm instead of 40mm: this can keep X axis walking smoothly; at the same time, this can also realize energy-saving and cost-reducing.3) Using V stick to replace V chuck: this can keep X axis glass cutting stable.4) Using synchronous belt: this can reduce the loss of servo motor.5) equipment through professional structural analysis software, ensure that the stability of the machine, dynamic balance, mechanical strength to achieve the perfect coordination, and ensure the table structure deformation;6) the whole cable, trachea layout is reasonable, completely sealed;7) guide only with high-speed mute linear guide rail, cutting high accuracy, low noise;8) the use of advanced Japan yaskawa portions of the servo motor, make the equipment reliable performance, small error, high efficiency;9) cutting operation in Japan SMC proportional electromagnetic valve, according to the glass thickness automatically adjust the pressure, rotate 360 degrees of the cutting tools, top and bottom cushion under the knife cutting (can be accurate cutting any straight lines and various special-shaped glass), crawl cutting head is equipped with wheel, effectively prevent the assembly of the cutting tools and glass of accidental damage;10) segment containing the knife protection function, if the head of the gap on the outside of the glass or glass, program automatically stop, effectively prevent the damage to the parts and glass;11) conveyer, synchronous automatic transmission device, convenient for glass and transmission;12) positioning device, photoelectric scanning positioning system with mechanical positioning and;13) compensation function, cutter eccentricity compensation, clearance compensation, pitch compensation.

5. Mechanical configuration1), main bearing, NSK (Japan);2), guide rail, THK (Japan)/HIWIN (Taiwan)3), gear and rack : GUDEL (Switzerland)/ATLANTA (Germany)4), knife wheel/tool holder: Germany bole (Germany);5), mat: imported industrial felt (black);6), bedplate: special waterproof board.7) bridge X y : Mn6. Electric configuration1), power supply voltage: 380 v / 60 hz,2), air pressure: 06- 0.8 Mpa; Provided (users supply);3), servo system: yaskawa servo motor (Japan);4), frequency converter, in (Taiwan);5), transmission reducer: thunis (taizhou);6), proportional valve, SMC (Japan);7, the electromagnetic valve: Airtac(taiwan);8), motion control system and optimization software:Optima (Italy)9), ac contactor, schneider (France).10), motor circuit breakers: schneider (France);11) Circuit breaker: schneider (France)12)proximity switch:Omron (Japan)8. The software part;1), form a complete set of professional cutting system and cutting optimization software; (optima) 2), the motion control system and optimization software for Italy (Optima);3), parameter adjustment is simple, operators need to modify the parameters of the less, simple and intuitive, the operating personnel Requirements is low, easy to learn.4), atlas nesting programming, appoint the alien from gallery, set the related parameters, the processing quantity, automatic nesting, automatic generating machining trajectory;5), form a complete set of AUTO CAD drawing software compatibility;Cut glass size 6, direct input, automatic optimized cutting directly;6) opti-way: two softdog can be connected from computers between machine and office, easy to control management orders. 7), with automatic correction function. To ensure that the cutting accuracy;8), cutting path selection function. Make sure the best cutting speed;9), the origin correction function. Can be set in a secondary origin;10), photoelectric positioning function, according to the actual position and the deflection Angle, automatic adjustment of cutting;11), automatically adjust the cutting knife pressure function, to ensure optimal cutting effect;, all kinds of protection: including hard and soft limit, knife pressure limit, external stop control and so on.With functions of automatic design and print labels and scan.glass breaking machine briefly;

5. Mechanical configuration1), main bearing, NSK (Japan);2), guide rail, THK (Japan)/HIWIN (Taiwan)3), gear and rack : GUDEL (Switzerland)/ATLANTA (Germany)4), knife wheel/tool holder: Germany bole (Germany);5), mat: imported industrial felt (black);6), bedplate: special waterproof board.7) bridge X y : Mn6. Electric configuration1), power supply voltage: 380 v / 60 hz,2), air pressure: 06- 0.8 Mpa; Provided (users supply);3), servo system: yaskawa servo motor (Japan);4), frequency converter, in (Taiwan);5), transmission reducer: thunis (taizhou);6), proportional valve, SMC (Japan);7, the electromagnetic valve: Airtac(taiwan);8), motion control system and optimization software:Optima (Italy)9), ac contactor, schneider (France).10), motor circuit breakers: schneider (France);11) Circuit breaker: schneider (France)12)proximity switch:Omron (Japan)8. The software part;1), form a complete set of professional cutting system and cutting optimization software; (optima) 2), the motion control system and optimization software for Italy (Optima);3), parameter adjustment is simple, operators need to modify the parameters of the less, simple and intuitive, the operating personnel Requirements is low, easy to learn.4), atlas nesting programming, appoint the alien from gallery, set the related parameters, the processing quantity, automatic nesting, automatic generating machining trajectory;5), form a complete set of AUTO CAD drawing software compatibility;Cut glass size 6, direct input, automatic optimized cutting directly;6) opti-way: two softdog can be connected from computers between machine and office, easy to control management orders. 7), with automatic correction function. To ensure that the cutting accuracy;8), cutting path selection function. Make sure the best cutting speed;9), the origin correction function. Can be set in a secondary origin;10), photoelectric positioning function, according to the actual position and the deflection Angle, automatic adjustment of cutting;11), automatically adjust the cutting knife pressure function, to ensure optimal cutting effect;, all kinds of protection: including hard and soft limit, knife pressure limit, external stop control and so on.With functions of automatic design and print labels and scan.glass breaking machine briefly;

1. The equipment of institutions;Framework is mainly composed of institution, snapping piece structure, pneumatic control system and electric control system of four most.2. Electrical parts;1), contactor, People/chint(Hangzhou)2).button: People/chint(Hangzhou)3)breakers: People/chint(Hangzhou)4), main control vacuum electromagnetic valve: the DE guest (Taiwan);5) and other pneumatic components: DE guest (Taiwan);6, fan: anddrunkenness (Zen Buddhism, Lida).3. The mechanical;1), mesa: special waterproof board;2), mesa: imported industrial felt (black);3), broken rod: solid wood (grey).Note: five.1), on the line to achieve automatic, automatic transmission, automatic cutting machine, automatic break function;2), the operator: the piece: 0 people (automatic tablet without personnel operation);Cutting: 1 people understand the computer basic operation ();Bye the piece: 1-2 people (glass break experience);3), the cutting efficiency: 30-70 seconds per piece;4), features: a, no special requirements to operators, the operation is simple, convenient for management;B, safe and efficient, automatic on Taiwan effectively to ensure the safe operation and to prevent the occurrence of broken glass, automatic conveying device to reduce the workload of the operator;C, high cutting precision, good stability and can satisfy the need of all kinds of production, and effectively safeguard processes after the processing quality and reduce the processing difficulty;D, high IQ cutter optimization software, can significantly improve the utilization rate of glass to reduce the production cost, powerful gallery can guarantee can do all kinds of shaped glass cutting equipment, can satisfy the demands of various orders cutting;E, cutting machine, automatic filling and pressure automatic mediation function, effectively guarantee the stability of glass cutting machine and cutting effect;, equipment to the buyer factory car, electricity, gas and water shall be the responsibility of the buyer6. Attachment: floor plan. (can be ordered according to the site layout)Note: the table with each additional one station, line the total length of 5.8 meters.

1. The equipment of institutions;Framework is mainly composed of institution, snapping piece structure, pneumatic control system and electric control system of four most.2. Electrical parts;1), contactor, People/chint(Hangzhou)2).button: People/chint(Hangzhou)3)breakers: People/chint(Hangzhou)4), main control vacuum electromagnetic valve: the DE guest (Taiwan);5) and other pneumatic components: DE guest (Taiwan);6, fan: anddrunkenness (Zen Buddhism, Lida).3. The mechanical;1), mesa: special waterproof board;2), mesa: imported industrial felt (black);3), broken rod: solid wood (grey).Note: five.1), on the line to achieve automatic, automatic transmission, automatic cutting machine, automatic break function;2), the operator: the piece: 0 people (automatic tablet without personnel operation);Cutting: 1 people understand the computer basic operation ();Bye the piece: 1-2 people (glass break experience);3), the cutting efficiency: 30-70 seconds per piece;4), features: a, no special requirements to operators, the operation is simple, convenient for management;B, safe and efficient, automatic on Taiwan effectively to ensure the safe operation and to prevent the occurrence of broken glass, automatic conveying device to reduce the workload of the operator;C, high cutting precision, good stability and can satisfy the need of all kinds of production, and effectively safeguard processes after the processing quality and reduce the processing difficulty;D, high IQ cutter optimization software, can significantly improve the utilization rate of glass to reduce the production cost, powerful gallery can guarantee can do all kinds of shaped glass cutting equipment, can satisfy the demands of various orders cutting;E, cutting machine, automatic filling and pressure automatic mediation function, effectively guarantee the stability of glass cutting machine and cutting effect;, equipment to the buyer factory car, electricity, gas and water shall be the responsibility of the buyer6. Attachment: floor plan. (can be ordered according to the site layout)Note: the table with each additional one station, line the total length of 5.8 meters.

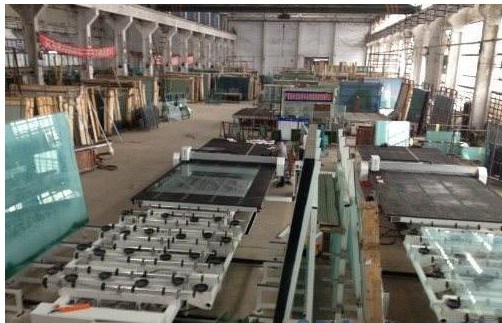

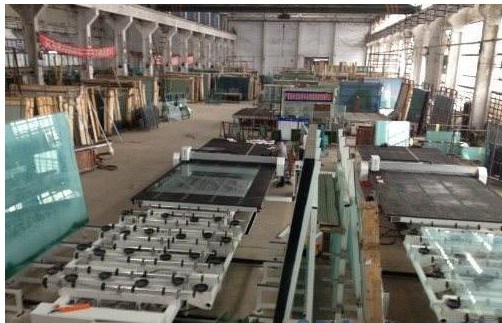

Nanjing Flourish International Company established in 2015, composed of three glass machine production factories and three glass processing factories with more than 20 years production and research, has developed into a giant group company integrating glass machinery and glass R&D, manufacturing and trade, is a leading enterprise in glass processing equipment and glass manufacturing. We stick to customer first, service foremost principle, providing excellent product at very competitive and reasonable prices. We focus both on good product quality and also heartfelt after sales service.

Our glass machine includes glass cutting machine (including whole line: Glass loading table, glass cutting table and glass break off table as well as integrated multi-function glass cutting table), glass washing machine both horizontal washing machine and vertical washing machine, glass edging machine, such as straight line bearing structure edging machine and straight line chain type edging machine as well as double edger and four side edging line, whole lamination machine including glass washing machine, glass pre-pressing machine, pneumatic sucker, film combination table and autoclave used for both architectural and auto glass production, bending furnace of single wagon, double wagons, triple wagons and series wagons, insulation machine/IGU line with full accessories, digital UV flat bed printing machine, silk screen printing machine and infrared drying line and 3D art machine etc, glass engraving machine, sandblast machine, glass drilling machine and acid etched machine as well as glass frosting machine, water jet, etc. Through over 20 year's development, we believe we can provide expert consultancy for both newly established glass processing factories and those old renovation glass processing factories to help them success in reputation and profits. All of our machines are certified by ISO9001, CE, etc.

Our three glass processing factories are located in Jinan, Nanjing and Wuxi, we produce building/architectural glasses such as tempered glass, laminated glass, insulating glass, tempered laminated glass, tempered insulated glass, lowe insulated glass, silkscreen/serigraph glass, colorful ceramic glass, bulletproof glass, fireproof glass, frost glass, stained glass, patterned/figured glass, acid etched glass and various types of art glasses etc. Our glasses are widely used for glass faç Ade, glass curtain wall, handrails, elevators, ceilings, floors, partitions, windows and doors, balconies, railways, sound barriers, bathrooms, furniture and electric appliance etc., Our glass service has also expanded to hardwares like spiders, spigots, hinges and locks, as well as handrail hardwares. We are certified by ISO9001, China national safety authentication of "CCC", CE certification, Australia AS/NZS2208 and USA SGCC standards etc.

All of our products are well exported to almost all countries and regions such as Germany, France, Italy, Netherlands, Belgium, the United States, United Kingdom, Holland, Singapore, Honking, Malaysia, Canada, Vietnam, India, Dubai, Kenya, South Africa and some other Middle East and Asian counties etc.

We sincerely welcome you to contact us for more information regarding glass machine and glasses or accessoris. We will provicde expert advice for you in terms of factory layout, machine/glass procurement, glass installations. etc., Our goal is to get win-win result.