Woodworking Multi Head Rotary CNC Cutting Machine

| Price: |

US $ 18000-30000/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,Western Union,Paypal |

| Prod Model: |

VCT-3512R-6H |

| Machine Size(X*Y): |

2600X2000mm |

| Spindle Power: |

2200wx6PCS |

| No. Of Rotary: |

6 PCS |

| Motor Driver: |

6PCS Panasonic Servo Motors |

| Rotary Transmission: |

Gear Box (Reduction Rate: 1:25 |

| Xyz Transmission: |

Tbi Ball Screw 40mm for Z Axis, Gear Rack for Xy |

| Max Engraving Speed: |

15000mm/Minute |

| Air Cylinder Support: |

Yes (300mm Long Air Cylinder) |

| Oil Lubrication System: |

Yes |

| Controller: |

4 Axis Nc Studio Controller with Handle Wheel |

| Spindle Layout: |

Vertical |

| Feed Mode: |

Mechanical |

| Controlling Mode: |

CNC |

| Certification: |

ISO |

| Spindle Number: |

6 Heads |

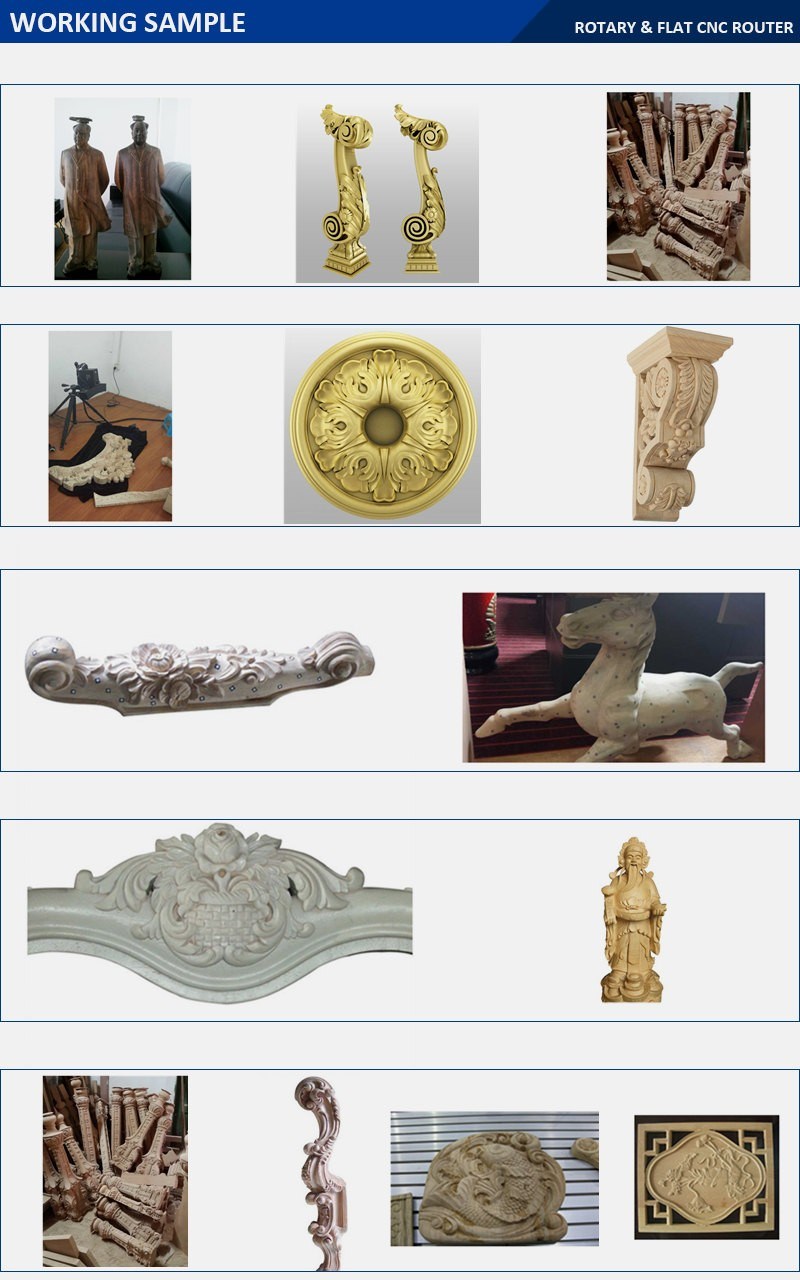

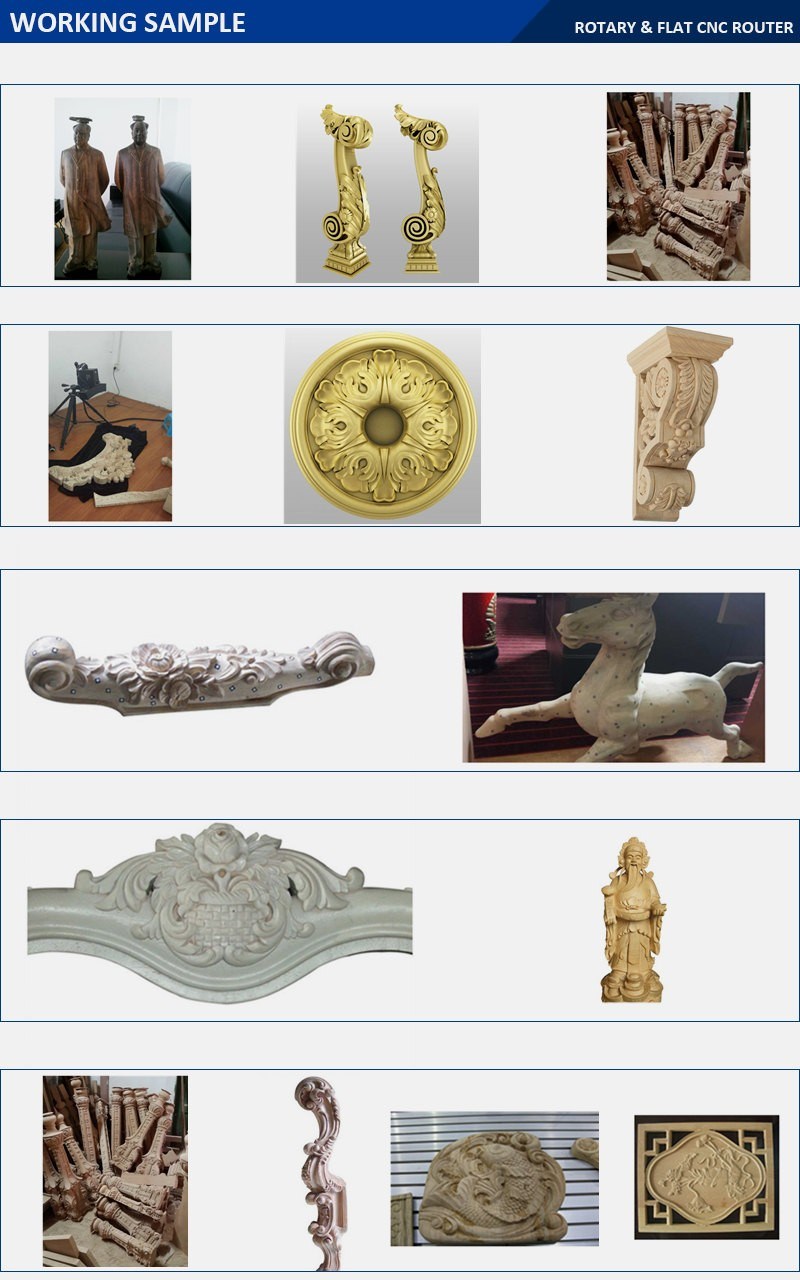

Product Description

Heavy Duty Wood working Multi Head Rotary CNC Cutting Machine (VCT-3512R-6H)Features:

1. Adopted heavy-duty industrial seamless welded design, construction and welding anti-deformation finite element method, and low-temperature annealing by the CNC to ensure optimum strength and rigidity.

2. Use power mill software to make special design for realize 4 axis (XYZA) movements at the same time to realize 3D rotary engraving column material.

3. Max. Z axis plate width is 900mm, ensures the balance during working to avoid vibration.

4. Use gear rack locking system instead of common screws to adjust and fix the rotary device, more tight and stable.

Applications:

Material: engraving and cutting wood sheet, PVC, ABS Sheet, aluminum sheet, brass, etc.

Field: Mostly used for making antique furniture, Mahogany furniture, European style furniture, doors, windows, stairs, handrails, Buddha, kitchen cabinet, bookcase, etc.

Technical Parameters: | Model | VCT-1590R-4H | VCT-3512R-6H | VCT-2512R-8H | VCT-2013R-2Z-8H |

| Dimension(X*Y) | 1100×1500mm (3.6'x4.9') | 2600 x 2000mm

(8.6'x6.6') | 2500 x2000mm

(8.2'x6.6') | 2100×2000mm

(6.9'x6.6') |

| 3D Rotary Working Size | 900mm(length) x 150mm(rotary diameter) | 1200mm(length) x 350mm(rotary diameter) | 1200mm(length) x 250mm(rotary diameter) | 1300mm(length) x 200mm(rotary diameter) |

| Spindle Power | 1500W×4PCS | 2200W×6PCS | 2200W×6PCS | 2200W×8PCS |

| No. Of Rotary | 4 PCS | 6 PCS | 8 PCS | 8 PCS |

| Motor Driver | Stepper Motors (8pcs) | 6pcs Panasonic Servo Motors

(2pcs support rotary, 1pcs for X axis, 1pcs for 2Z, 2pcs for Y axis) | 7pcs Panasonic Servo Motors

(2pcs support rotary, 1pcs for X axis, 2pcs for 2Z, 2pcs for Y axis) |

| Rotary Transmission | Belt Transmission | Gear box (reduction rate: 1:25) /Belts transmission is optional |

| XYZ Transmission | TBI Ball Screw for

XYZ axis | TBI Ball Screw 40mm for Z axis, High precision Gear Rack for XY axis |

| Max Engraving Speed | 12000mm/m | 15000mm/minute |

| Air Cylinder Support | Yes (300MM long air cylinder) |

| Oil Lubrication system | Yes |

| Tool Diameter | 4,6, 8, 12mm |

| Body Structure | Thick steel tube welding |

| Guiding Rails | XYZ Taiwan Linear Square Rails |

| Reposition Accuracy | <0.03/300mm |

| Spindle Speed | 6000~24000rpm |

| Controller | 4 axis NC Studio Controller with handle wheel ( PC control ) |

| Format of instructions | G code or HPGL |

| Voltage | 380V/60Hz or 220V/50HZ |

| Weight | 600KG | 2500KG | 2100KG | 2000KG |

| Packing size(L*W*H) | 1485x 1300x1750mm ( 3.38CBM) | 4200x2200x2200mm (20CBM) | 2700×2200×2200mm(13.1CBM) | 2700×2200×2200mm(13.1CBM) |

Machine Details

1. Base Frame: The heavier base frame is made of heavy-duty tubular steel that is welded, precisely machined by gantry milling machine and stress relieved by vibration device so that the foundation remains true and steady over the operational life of the machine.

2. Multiple Cooling Spindle: Multiple spindles for mass processing on solid wood, MDF, acrylic, aluminum and plastics, etc; we offers different spindle options which available with 220V-2 Phase-50-60Hz or 220V-3 Phase-50-60Hz or 380V,3Phase-50-60Hz.Series of tools are available, for example, diameter 3.175mm,4mm,6mm,8mm and 12.7mm.

3. Ball Screw: Use TBI ball screw for Z axis, anti-Backlash center driven ball screws with 25mm or 40mm diameter and 0.01mm repositioning accuracy.

4. Gear rack: XY axis use high accuracy gear rack. The combination for ball screw and gear rack makes machine working more accurate and stable.

5. NC Studio 4 AXIS Controller: 85A model. PC based NC Studio Controller with friendlier human& machine interface/HMI, fully executed with computer. It well realizes high-speed and high-precision motion control. Handle wheel can be used to control the movement of machine.

6. Servo Motor: AC Panasonic Servo motor for more smooth motion and triple working speed and they require no regular maintenance.

7. Rotary Axis: Available with different cylinders, irregular objects, crutch and cylinder crafts with various diameters; we can put different number of rotary axis according to specified requirement.

8. Control Cabinet: All the electrical components are housed and wired in a mobile, double door electrical enclosure. This allows for easy access and service when needed. Every wire is tagged so that when service is required, the customer can easily navigate the cabinet.

9. Central Lubricator: Easier to lubricate the Guide units regularly, just pull it gently and oil will go when it is needed.

10. 4 AXIS Software: You can use power-mill software to make processing of 3D files which was scanned with 3D scanner. We can make 4 axis movements, AXYZ axis can move at the same time.

Optional

1. 3D Scanner: with the 3D scanner you can scan any objects which you want to make by machine, input the scan file generated by scanner to computer, and process it with postprocessor software, saved it as G code which can be recognized by CNC router.

2. Control cabinet with air conditioner: the air conditional installed on the control cabinet, ensure the machine can be used in tropical area countries to reduce the tempreture inside of the cabinet, avoid damage of the electric components

CNC Engraving and Cutting Solution Provider

WILLIAM CNC is a Chinese manufacturer of CNC router, Laser marking machine, label cutter, flatbed cutter, and cutting plotter, having its own manufacturing base and official license for export & import business. Our brand (VICUT) focuses on overseas market, to provide the customer CNC machinery with an affordable solution without sacrificing options or function.

With our CNC router or laser marker, you can cut, carve, or mark on many kinds of materials, such as wood, acrylic, metal, stone, foam, glass, plywood, MDF, PVC, ABS, etc. With our flatbed cutter, label cutter or cutting plotter, you can make digital cut on vinyl adhesive, reflective film, craft paper, sandblast membrane, stickers, cardboard, plastic board, rubber sheet, marking film, PET, PP, PVC, PC, wall paper, coated paper, glossy paper, paper jam, etc.

Remember that each solution can be customized for your particular needs. So no matter what you cut, engrave, or mark, we can configure a machine to suit your applications and budget. We also welcome overseas agents to join the growing families of VICUT.

Market: Now the market is mainly distributed in North America, South America, Europe, Oceania, Middle East, Southeast Asia, South Asia and West Asia. We have established cooperative relationship with hundreds of clients in nearly 30 countries. We are actively looking for new partners to explore the new market, to achieve win-win. We prefer to provide valuable product, service and solution for more end users. We appreciate you join us, to be partner in business, to be friend in life, to be one family forever.

Product: We produce CNC engraving and cutting machinery, such as CNC router, laser marking machine, label cutter, flatbed cutter, cutting plotter. We offer customized service according to your special requirement, such as, shape, dimension, color, specification and structure design, etc. OEM is available.

Team: We have two workshops in Hefei city, Anhui province. 200 employees in all, 50 percent workers have over 5 years manufacturing experience. More than 20 experienced engineers and designers in R&D department focus on improving and updating products, to meet with market. More than 20 sales people have excellent skills both in technology and international business service. All the service engineers have experience in providing technology service in overseas market. Support remote training and door-to-door service. Help is always just one call or email, and then we can provide a suitable solution promptly by analyzing and estimating the problem.

Quality Assurance: Strict whole process quality control and management during procurement, manufacturing, packing, and shipping. Cooperate with top suppliers of CNC spare parts in the world, such as Italy HSD, Japan Panasonic, Taiwan Syntec, Taiwan PMI, TBI, France Schneider, Dragoncut software, etc.

Transportation: Welcome to visit our company. By fast train, it takes about three hours from Shanghai or Qingdao, two hours from Wuhan, one hour from Nanjing. By plane, needs less than 2 hours from Beijing or Guangzhou. Any port in China can be used for shipment, and Shanghai or Nanjing port is more closed to our factory.