| Shaping Mode: |

Injection Mould |

| Application: |

Hardware |

| Installation: |

Fixed |

| Plastic Material: |

PP, ABS,PC,PE,Nylon and So on |

| Runner: |

Hot Runner or Cold Runnerot Runner or Cold Runner |

| Design Software: |

RO/E, Ug, Catia, Solidwork, Moldflow, Autocad |

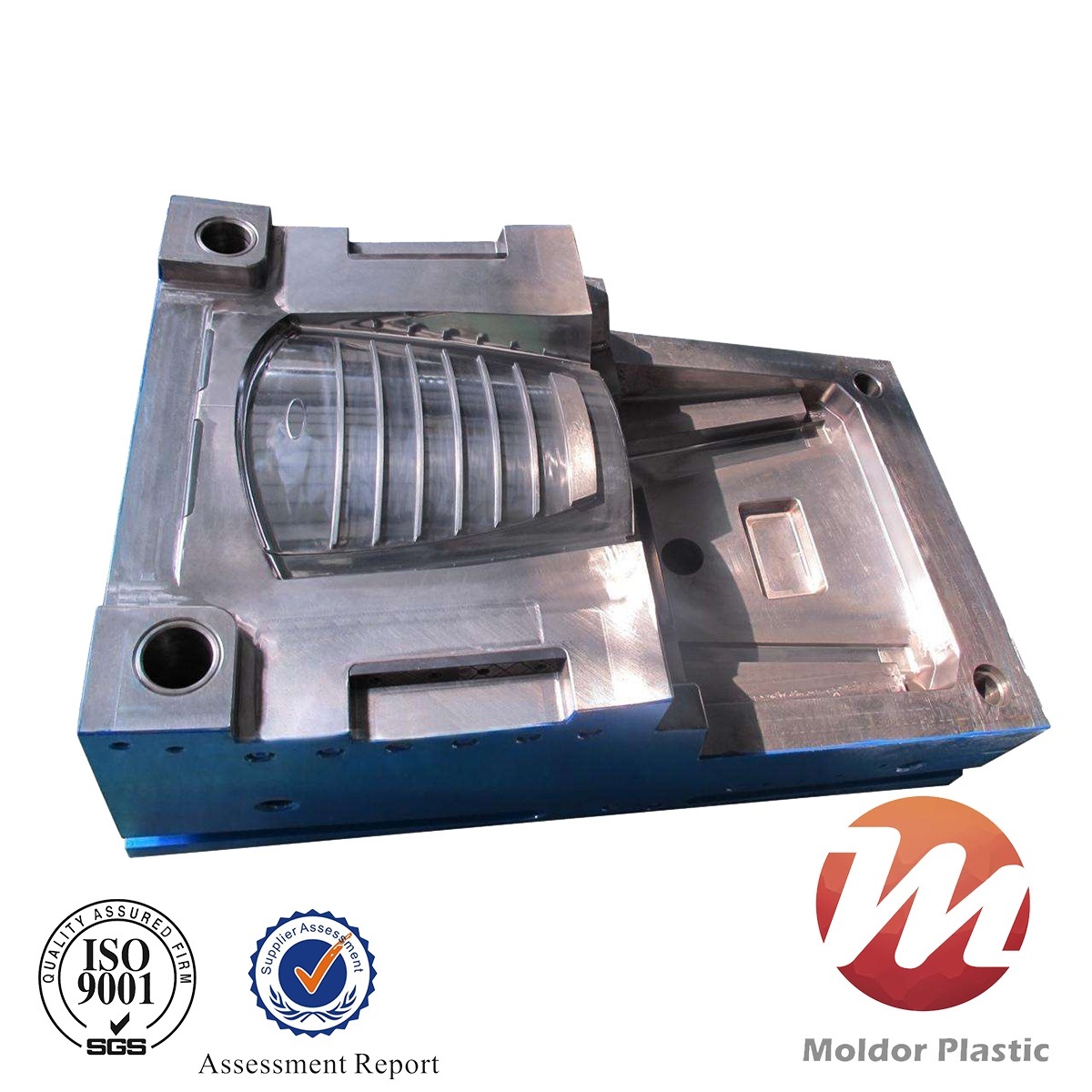

Product Description

INTRODUCTIONMoldor has over thirty years of Injection Molding Expertise. Especially in plastic mold manufacturing with our knowledge we can provide outstanding service to fulfill all your molded part requirements. Our Facility and technical ability will exceed your expectations on service, quality and value.

We currently have a wide variety of Molding equipment ranging from 50 to 360 tons for Plastic Injection Over Molding , including Horizontal& Vertical versions.

Our injection moulds and injection moulded plastic parts are widely used in Electronics, household appliances, medical devices, sporting goods, and promotion gifts fields.OUR SERVICE1.Product Design,Structural Optimization,Process Optimization

2.Mold Making,Plastic Molding Parts,Casting Parts,Machining Part

3.Manage Project,Control The Delivery and Quality of Products

4.Arranging the Transportation,Customs Clearance and other Matters for YouSPECIAL INFO. | Product Name | Plastic injection mold for plastic parts |

| Mold Shaping | Customized die casting mold |

| Nos of Cavity | Single or multi as your requierment |

| Design Software | UG, PROE, CAD, etc. |

| Plastic Material | PP, PC, PS, POM, PE, ABS, etc. |

| Mold Life | 300000 - 1000000 shots |

| Runner | Cold or Hot |

| Delivery Time | 15 - 30 days after deposit |

| Payment Terms | T/T, Paypal, Money Gram or others |

| Packaging | Wooden case for molds, Cartons for plastic products. |

OUR TOOLING DESIGN CAPABILITY

We are professional plastic mold and injection molding parts manufacturer. We can provide one-stop services for customer around the world. We have our own tooling design team from engineering, tooling, to custom injection molding.

1. Design for manufacturability and efficient production is our primary objective.

2. OEM is available according to the customers' drawing and 3D-data

3. We own advanced CAD/CAM/CAE systems to design the detail of the molds. Otherwise we have moldflow to simulate the feasibility of part and mold

4. We can provide the mold drawing with 5 working days for our customers. All the necessary technical drawings will be sent to customers for future mold maintenance references.

5. We have enough experience working with materials such as: PP, ABS, PC, PS, PMMA, POM, TPU, TPE and so on

6. We have our own mold design process. Showed as below

Mold Design Process

Phase 0/1Quotation phase:

Quoting Price based on customer's request and signing sales contract/stamping proforma invoice. Making the schedule

Input: customer's 3D data or 2D drawing, requirement of the product including material, color, reference of dimension and so on.

Output: exact quotation and BOM list for customers. Sign with customer sales contract or stamping proforma invoice.Phase 2Design phase:

starting the construction of 3D mold

Input: UG or CATIA data from customer.

Output: 80% feasibility 3D data of moldPhase 3DFM phase:

design for manufacture, sending customer the 3D/2D package of tooling for confirmation. Optimizing the mold data.

Input: PPT of DFM checking report.

Output: 100% complete 3D data of mold preparing for tooling manufacturing.Phase 4-1Manufacture phase:

starting manufacturing after design approved by customer

Input: 3D data of mold

Output: 90% complete moldPhase 4-2FOT testing Phase:

testing mold with noticing customer. Delivering the FOT part for approval. Doing the final polish or treatment for the mold after samples approved.

Input: 90% complete mold

Output: Optimized mold ready for SOPPhase 5 Serie production phase:

Starting series production of products.

Output: Supply product for customer OUR TOOLING MANUFACTURE AND INJECTION CAPABILITY

OUR TOOLING MANUFACTURE AND INJECTION CAPABILITYOur tooling work is able to make all side molds with single cavity or multi cavities. With your product data, our engineer can provide you the feasible project with low price and high quality. Below shows our tooling capability:

1. Maximum mold size 2500mm*2000mm*1500mm

2. Maximum mold weight: 15 ton

3. The highest machining precision: 0.01mm

4. The highest injection precision: +-0.03mm

5. Experience of high precision molds and custom injection molding for healthcare and high-grade appearance parts

6. The yearly production capacity of molds is over 250 set

7. Delivery time for each mold is from 25-45 days, depending its complexity

8. We equip our own high precision CNC machines, EDMs, Wire cut machines, mirror EDM,

three-coordinates measuring machine to ensure the quality of both mold and injection parts

CONTACT US

The prodecessor of Ningbo Moldor Plastic Co., Ltd. Was Ningbo Xuanye Plastic Mold Factory, which was established in 1998 in Ningbo, China, which has rich experiences in the mold and plastic industry.

Moldor can provide you the high-quality products at very competitive price because we have complete equipment and professional team. Through the long-term practice and experience accumulation, our molds and products are always very accepted by customers all over the world.

As a plastic injection molding company, we always want to be the best supplier in this industry. Our manufacturing base is located in the 'Plastic Kingdom'- Yuyao, equipped with advanced machines and skilled workers. Moldor is using international advanced CAD CAM CAE methods and integrated manufacturing systems to service customize all over the world. We have more than 30 plastic injection moulding making machines, including CNC machines, Digital control EMDs and EWCs for moulds fabrication. As well as over 40 Digital-controlled plastic injection moulding machines from 50T to 600T for molded parts production which can handle plastic parts from 0.1g to 3500g. As a plastic moulding factory, we provide free quotation and advice, as well as free design service. Overmolding, insert and outsert moulding, silk printing, ultrasonic welding, assembly and packing services are available. We are trying to offer the best service to be the No. 1 in China injection moulding factories. Meanwhile Moldor strictly implements the ISO9001 quality assurance system, each production lines are equipped with very perfect and the QC system.

In recent years, our factory is specialized in the production of tigger sprayers, lotion pumps, fine mist sprayers, crimp pumps, bottle caps, closures and many other cosmetic packaging.

We believe with our excellent quality and best service, Moldor will be stronger. We are sincerely invite you to cooperate with us for a long-term win-win partnership.