| Prod Model: |

HQ-C60 |

| Shaping Mode: |

Injection Mould |

| Process Combination Type: |

Single-Process Mode |

| Application: |

Furniture |

| Installation: |

Fixed |

Product Description

Do customized mould for you! "Making moulds, making art." Company has always uphold this principle and dedication to customer service.The product combined art and manufacture to satisfy customer's need.

Business Produce1.Making mould quotation according to customer's request.

2.Signing proforma Invoice.

3.Designing 2D/3D drawing based on customer's request.

4.Sending customer drawing for confirmation.

5.Manufacturing after drawing approved by customer.

6.Testing mould with noticing mould.

7.Delivering the samples for customer's approval.

8.Doing final polish for the mould.

9.Shipping by sea or others.

Our advantagesSuperior Price

High Quality

Rich Experienced Design

On Time Delivery

Good After-sale Service Our Service:- Providing final mould design drawing before processing mould.

- Providing a year free service guarantee.

- Providing service sincerely. Any questions, you can contact with us. We'll reply as soon as possible.

FAQ1,What's the delivery time?

30-45 days after the T/T deposit or L/C.

2,What's the payment?

T/T, 40% advance before mold designing, 30% after 1st try out sample delivering, 30% before shipment. L/C 100%

3,What's min order quantity?

1 set

Company Profile

As a top manufacturer of plastic injection mould, HQMOULD was founded in 1970, which is located in Huangyan Mould Town, Taizhou city. HQMOULD focus on manufacturing plastic injection mold for more than 30 years with superior quality, high-tech and fair prices. HQMOULD specialized in motor parts mould, crate mould, pipe fitting mould, commodity mould, crate mould etc. Up to now, HQMOULD has advanced plastic processing equipment and a strong production capacity.

R&D

HQMOULD has a strong R&D team, focusing on the pipe fitting mould, auto mould, logistics mould. HQMOLD is a professional plastic injection mould manufacturer, with advanced processing equipment, rich experience in injection molding. The experienced experts use CAD/CAE/CAM system to design the plastic mould and modify mold design drawing according to the requirement of customer.

Mold Procedure |

Product Analysis | Providing technical data and parameter of equipment by customers(sample, 2D/3D drawing, etc). |

Mould Design | Using CAD software to design mould structure. |

Mold flow | Using CAE software to optimize mold structure. |

technological research | Feeding back customers final mould processing plan and related technological parameter to confirm. |

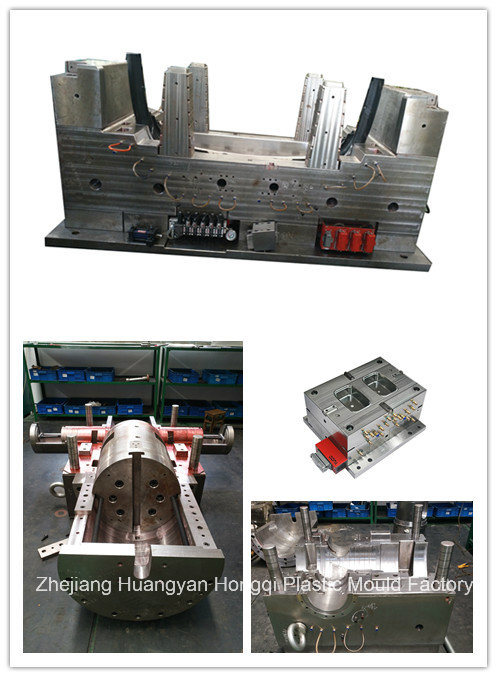

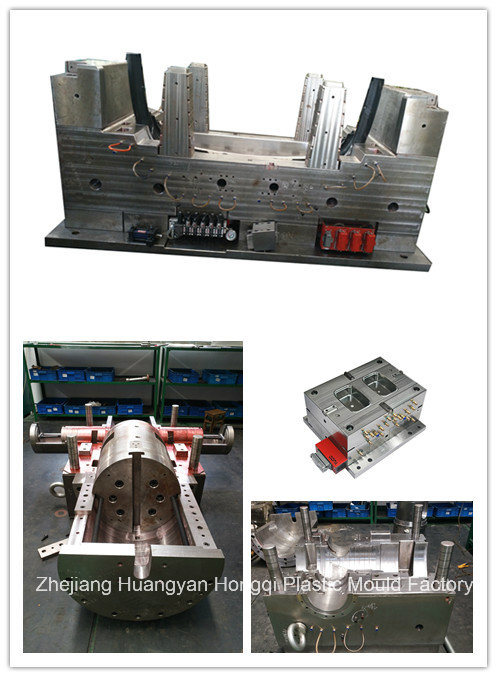

Above pictures for your reference

Contact Us

Tel:86-576-81107900

Mob:86-13456680008

Web:www.hqmould.com

Address:N0.818,Er Huan West Road,Huangyan,Taizhou,Zhejiang,China

HQ Mould, founded in 1970, is a private company specialized in manufacturing plastic injection mould. It is located in Taizhou Huangyan " Mould Town", a city with well developed moulding industry, as well as good environment, transportation and communication facilities. We have provided plastic moulds for home appliance, automotive parts, pipe and fittings, etc.

HQ Mould occupies totally 12, 000 square meters. We have more than 30 mould manufacturing machines such as: 5 Axis CNC, high speed CNC, milling machine, engraving machine, wire cutting machine, etc. With our advanced CAD/CAM, we provide great service of " product development, mould design, mould manufacturing, injection"

We now have 150 employees totally, including R&D engineers, tooling engineers, and office workers. We were awarded ISO: 9001 quality management system certification.

"Making Mould, Making Art", with high reputation our mould received worldwide welcome. We are committed to become the world's top mould supplier based in China, serving the world!