Categories

Categories

| Price: | US $ 0.1-0.5/Meter |

|---|---|

| Min Order: | 10000/Meter |

| Pay Type: | L/C,T/T,Western Union |

| Prod Model: | JC-NF011 |

|---|---|

| MOQ: | 1000 Kgs |

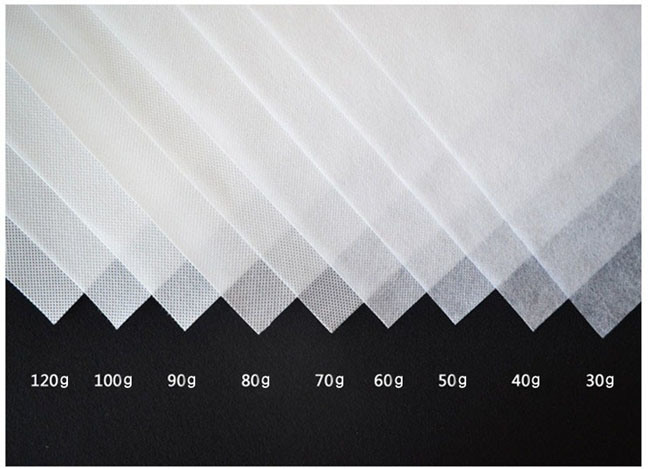

| Weight: | 30 - 300GSM. |

| Durability: | 3.3 Kg or More |

| Thickness: | 60 to 120g PP Non Woven Fabric |

| Supply Type: | Make-to-Order |

| Surface Structure: | Even / Embossed / Meshed |

| Material: | 100% Polypropylene |

| Usage: | Shoes |

| Feature: | Anti-Pull |

| Pattern: | Dot |

| Style: | Dyed |

| Technics: | Spun-Bonded |

| Width: | 58/60" |

| Weight Range: | 10-200GSM |

| Application: | Fashion Shopping Bag |

| Grade: | Domestic |

Item Name: Non Woven Fabric

*Material: 60 to 200g PP non woven fabric

*Printing:silkscreen/heat transfer printing/OPP film lamination

*Eco-friendly, durable and tear-resistant, waterproof

*Sew with high-quality yarn

*Customized designs, patterns, sizes and logos are accepted

*Ideal for homes, gift, supermarket, shopping, promotional and packing purposes

*Can be made foldable by plastic/metal button, zipper into square

1. PP spunbonded(SB), made according to customer requirements antibacterial, anti-static, anti-aging, hydrophilic, flame retardant and so on.

Packing: non-woven shopping bags, car seat covers.

Home: the end of the sofa cloth, aprons, hangers and so on.

Agriculture: Greenhouse with (anti-UV).

Medical: masks, shoe covers, bar caps, surgical clothing.

2. Meltblown:

Industry: oil, cotton, absorption felt, cloth (hydrophilic).

cleaning wipes: different design

Medical: filter masks, vampire films and so on.

3. Laminating non-woven

Packaging: shopping bags, car covers and so on.

Medical: medical bed sheets, disposable shoe covers, do non-slip treatment, corona treatment.

4. SMS: mainly used for charcoal bags, vacuum cleaner dust bags, protective clothing.

5. SF / SFS: protective clothing.

6. SPES: for down jackets, down proof lining, soft, tension is good, do not shed.

7. Ultrasonic laminated: do SMS, SFS, SFSC, SMMS, etc., can do a variety of other post-processing.

1.Product Description:

| Products | non woven fabric |

| Classify | pp nonwoven fabric for bags,furniture,medical,mattress,pillow cover,bedding sheet |

| Material | 25gsm-300gsm |

| Size | 160cm; 240cm; 320cm . 13sets machine |

| Application | 1.Industry: Roadbed cloth, bank cloth, filers, base for artificial suede and leather, auto covers, roof cover etc. |

| Color | black, white,red or custom made |

| Printing | 1, With LOGO printing, or the words/address/phone number printing and so on. you can choose the colors |

| 2, Design by yourself or our company is OK | |

| 3, No coating bags: max.4 colors | |

| 4, With coating bags: max. 4 colors | |

| 5, With BOPP film bags: max. 8 colors | |

| Technics | 1,Glossy/Matt Lamination, Embossing, vanish, aqueous coating, UV coating, 2,printing as your require, one side or two sides |

| MOQ | 5000pcs/stitch , 10000pcs/laminated, 20000pcs/heat seal |

| .Load weight | 8-10kgs |

| Packaging | can be packing in roll,such as 50m each roll and outside with strong plastic bag |

| Description | High strength, equal longitudinal and lateral. |

| Acid& Alkali-resisting, nonpoisonous, no harm to human's body | |

| Ventilation well | |

| Dyed with original color, never fades. | |

| Delivery time | The first container within 30 days after order confirmation |

| The later as per customers' requirements |

Q1: What's your product range?

Our Main products are non woven bags with/without lamination, PP woven bags, cooler bags, folding bags, drawstring bags, 190T bags, cotton canvas bag, jute bag etc. Our products are all LEAD/AZO/CADMIUM free.

Q2: How can I get some samples?

A: We are honored to offer you samples. You are requested to pay the plate cost & sample cost if it is a laminated bag.

Q3: How does your factory do regarding quality control?

A:"Quality is priority. Jichang people always attach great importance to quality controlling from the very beginning to the end.

Q4: What information should I let you know if I want to get a quotation?

We will offer you price referring to your detail request, please kindly inform us of the material, size, printing, closure, quantity and other requirements you prefer. If necessary, we can also give some advice for your reference.

Q5: How many days will sample be finished? And how about the mass production?

Generally, 5-7 days for samples making.

The lead time of mass production depend on quantity, production art, etc.

Usually, 25-30 days for 50000pcs shopping bag. 25-30days for 300,000pcs pp woven bag.

Q6: How do you ship the finished products?

-By sea.

-By air.

-By DHL, TNT, FEDEX, UPS, etc.

Q7: What advantages do you have?

-100% manufacturer, your professional and trustable supplier of PP woven bags.

-Any quotes will be taken seriously.

-Good advise and suggestions of your desired product will be given when needed.

-Superior quality with best factory prices

-Strict systems of management and quality control

-Shipment is well guaranteed.