Lzzg Brand Dehydrated Fine Sand Recovery Machine

| Price: |

US $ 10600-35895/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,Western Union |

| Prod Model: |

LZ Series |

| Delivery Detail: |

Shipped in 7 Days After Payment |

| Material Of Pump: |

Cr26 |

| Function: |

Recycling &Dehydration |

| Market: |

Asia, Africa, MID-East, etc. |

| Packaging Details: |

Wood or Nude |

| Application: |

Ore Dewatering |

| Max.Feed Size: |

10mm |

| Recycle Range: |

0.074-3mm |

| Material Of Screen: |

Polyurethane |

| Motor Type: |

AC Motor |

| Voltage: |

380V |

| Certification: |

CE |

| Warranty: |

1 Year |

| Customized: |

Customized |

| Condition: |

New |

| Type: |

Sand Recycling System |

| Weight: |

Depends |

| Material: |

Stainless Steel 304/ Carbon Steel |

| Material Feature: |

Fire/Heat/Oil Resistant |

| Color: |

Can Be Customized |

Product Description

LZZG Brand Dehydrated fine sand recovery machine

Brief Introduction:

Dehydrated fine sand recovery machine, we still choose polyurethane screen as its main screening part, check its structure, we add recycling part on TS de-watering screen:

1.sand after sand washer is fed onto polyurethane screen for de-watering

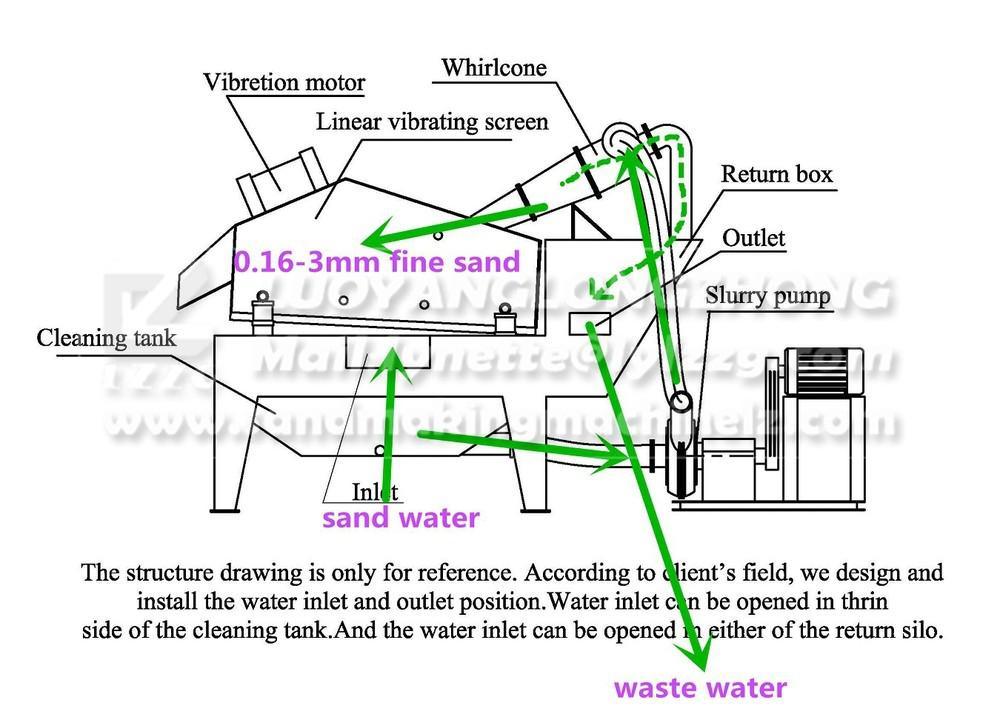

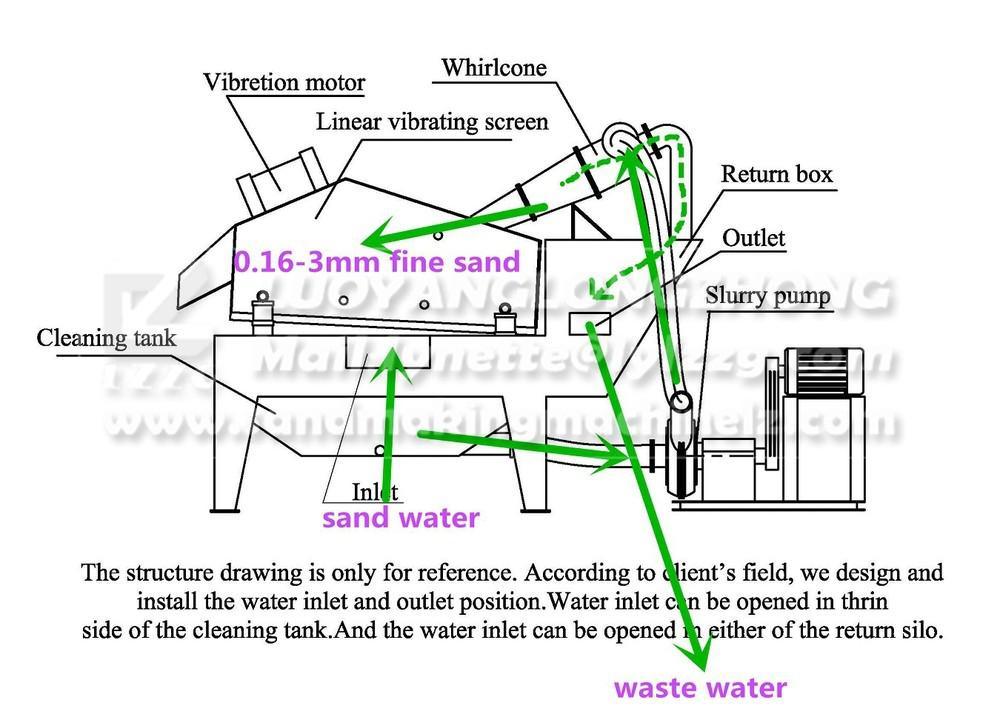

2.waste sand water through steel chute or rubber pipe in water tank and extracted by slurry pump into high pressure sediment seperator, fine sand 0.16-3mm is sprayed onto polyurethane screen also for de-watering, the waste water is back to return box and flowing out. Working process:

The sand and water mixture is sent to hydro cyclone. After centrifugal grading enrichment, the fine sand is sent to vibrating screen by sand sinking mouth. After dehydration by vibrating screen, the fine sand is efficiently separated from water and a few of fine sand and clay come through material returning bin then come back to purge tank. When liquid surface in the purge tank is high, the discharge hole can adjust the liquid surface. The weight concentration of recycling materials in line vibrating screen is 70%-85%. Adjusting fineness modulus can be realized by changing pump rotation speed, changing pulp consistency, adjusting overflow water and changing sand sinking mouth. By the process above, the fine sand recovery system can finish three functions, cleaning, dehydration and grading.

It consists of motor, pump, cyclone, TS linear vibrating screen, washing trough, and returning material box.

Advantage:

1: Effectively reduce the fine sand losing quantity, and make it in the scope of 5%.

2: The vibrating screen utilizes polyurethane screen cloth, which has longer life compared with others and uneasy to be blocked.

3: Inner the polyurethane, strengthen the whole device service life, it can smoothly finished the work of condensing slime and clearing the liquid etc.

4: The maximum fine grain materials quantity recovered from the total effluent is 95%, so it has unsurpassed technology and economic advantage compared with other equipment.

5: The find sand are recovered sufficiently, you can reduce the sedimentation basin workload and Low its clean cost.

6: Reducing nature stock time of the fine material, they can be transferred directly and supplied to the market.

7: We can design corresponding solve project according to our consumers, different requirements

Specification:| Model | Pump | Mud sand separation | Sieve dehydration (double) | Productivity (m³/h) | Weight (kg) |

| Power(kw) | Material | Specifications(mm) | Material | Power(kw) |

| LZ15-75 | 37 | Cr26 | 2*350 | PU | 2*3 | 180-350 | 5650 |

The respectable longzhong machine customers, thank you for choosing longzhong's products, Longzhong machine brand series of mining machinery, it is an intergration of senior refined and cusp, with better quality and performance among the same type of products. for the sake of your better usage, please read the instruction carefully and follow the instructions!

Working Principle:

Parts of Machine:

Applying Field:

LZ series fine sand recycle equipment has absorbed foreign advanced technology and its designing is combined with sand field actual situation, it possess the international advanced level, widely used in mud purification, artificial sand production line, hydropower station and sand aggregate system, glass raw material processing system and coarse slime recovery, and fine material recovery.

FAQ:

1.Is your product in stock?

Yes,once you place the order,the delivery will be done within one week.

2.Can the machine parts be replaced?

Yes,You can get them directly from us in a low price, and we make sure the easy maintainence and replacement .

3.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every product before delivery.Please check our working site. If our quality is not good, i don't think we can sell so well.

4.Guaranteed?

Yes. If products'quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

5.How about price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that " for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity".

6.Service and Payment Terms?

Payment:We usually accept T/T, L/C; T/T: 30% in advance as down payment, the balance before delivery;

Service:We take pictures of finished products before delivery.

Certification:

Contact Information:

LZZG-Luoyang Longzhong Heavy Machinery Co., Ltd.

Tel: +86-379-65160016

Mobile: +86-15090165004

Fax: +86-379-65160018

Website:

www.lylongzhong.en.alibaba.com

www.lzzgchina.com

Luoyang Longzhong Heavy Machinery Co., Ltd. is an international enterprise specialized in R & D, production and marketing of mining machinery and industrial milling equipment. Our company develope the production of mining machinery and industrial milling equipment, crusher products are widely used in mining, metallurgy, construction, chemical, power, steel and other industries.

Since its inception, the company quickly occupied the global market by its reliable product quality and perfect after-sales service. Our company has passed ISO9001-2008 quality certificate, The products are exported to Europe, Australia, North America, South America, Southeast Asia, the Middle East, Central Asia, Africa and other countries.

The company has senior design engineers of the mining machinery and industrial milling equipment, domestic and foreign famous universities, degrees, and other technical elites, to provide an inexhaustible driving force for sustainable development of enterprises, and they work together to ensure the long product development, design, production and after-sales service in every aspect of efficient and perfect.

Our main products include:

1) Washing and Screening Plant: Sand Washing Plant, Sand Recycling Machine, Vibrating Screen, High Frequency Linear Screen, Vibrating Feeder, Belt Conveyors and etc.

2) Crushing Plant: Jaw crusher, hammer crusher, impact crusher, VSI crusher and so on.

3) Grinding Plant: Coarse grinding mill, high pressure mill, ball mill, Raymond mill and so on.

Company based on market demands, always adhere to the development strategy of large research and development, precise production, and excellent service, by virtue of the excellent quality products and efficient service to meet customer needs, so that the Luoyang Longzhong Heavy Machinery thinks globally! We will fully meet your diverse needs, and cast your new brilliant!