Categories

Categories

| Price: | US $ 0.1-0.5/Piece |

|---|---|

| Min Order: | 2000/Piece |

| Pay Type: | T/T,Western Union,Paypal |

| Prod Model: | QN-custom made |

|---|---|

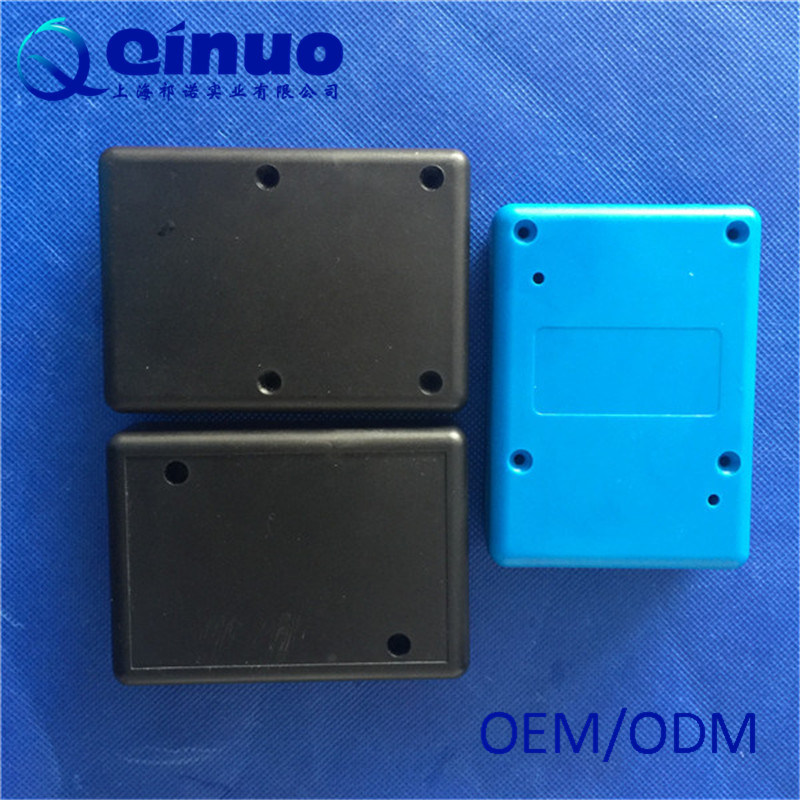

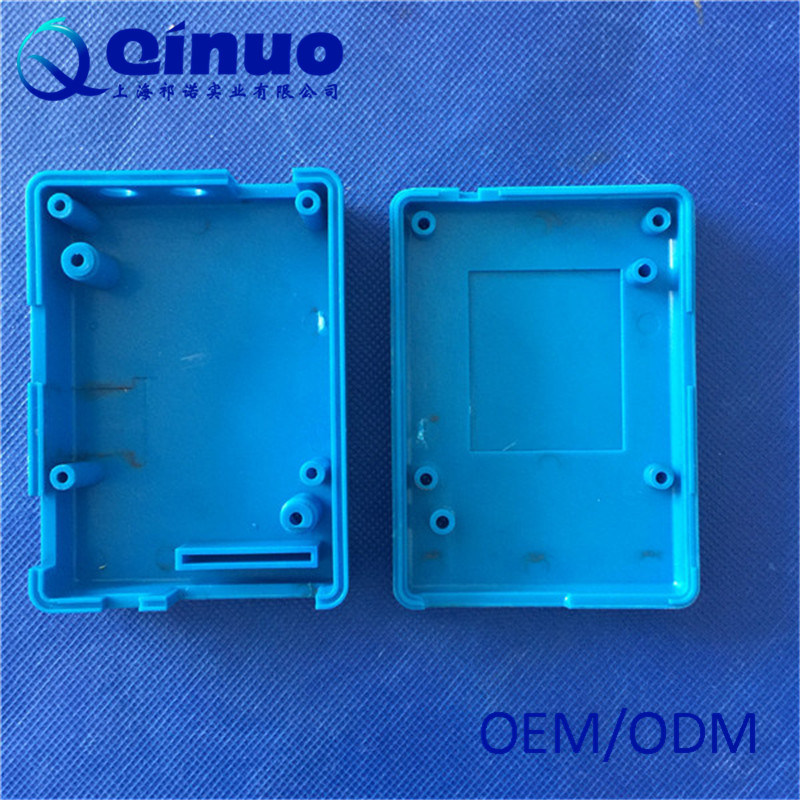

| Material: | ABS |

| Technology: | Injection |

| Color: | Customized Color |

| Size: | Custom Size |

Shanghai Qinuo Industry Co. Ltd was established in 2003, is a new and high-tech enterprise integrating R&D, production and sales. Since its inception, we adhering to the "Quality for Survival, Innovation Competes For Development " concept, continuous development and innovation, we won a good reputation at home and abroad.

Our company provides professional plastic parts, rubber parts and maching parts design and production services, products mainly used in automobiles, household appliances, machinery equipment and oil industry and other fields. We have a professional production and sales team, "High-Quality, High Professionalism, High Efficiency" are the principles of doing things.

We have two factories, more than 30 injection molding machines, molding machines and CNC lathes. Our company is located in Pudong New Area, Shanghai. Elegant environment, convenient transportation, Only need 30 minutes from our company to Pudong Airport.

We adopt comprehensive quality management system, all components passed ROHS certification, our products are mainly exported to the United States, Canada, Britain, Germany, Finland, New Zealand, Australia and other countries and regions.

High quality service:

| Item | Professional Service |

| 1 | Provide OEM/ODM service |

| 2 | Provide professional plastic mould design and manufacturing serivce |

| 3 | Provide plastic parts moulding/ printing/ painting service |

| 4 | Provide plastic parts assembly service |

| 5 | Provide plastic parts package service |

| 6 | Provide After-Sales service |

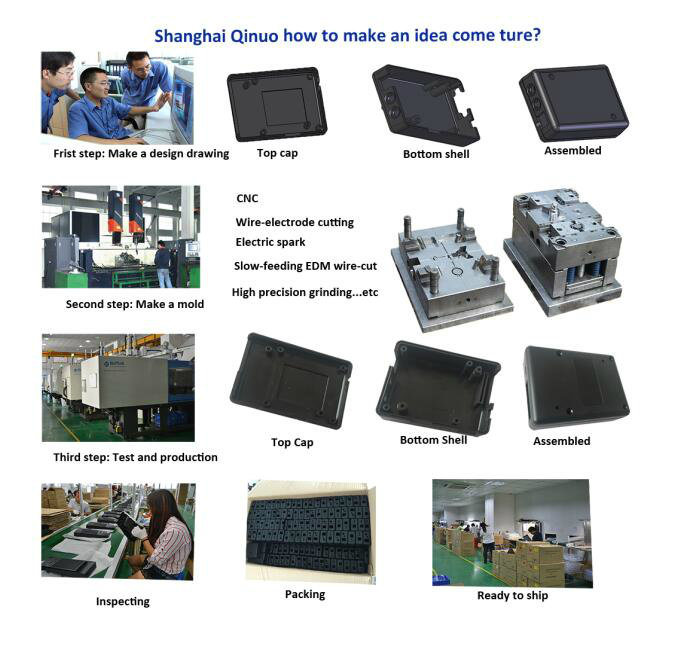

Our main service: From Design to Real Object Injection Moulding: One of the most common plastic manufacturing methods, injection molding lends itself to mass production of products ranging from cell phone stands to toys. The injection molding process melts resin pellets inside the injection machine with a heated barrel. An auger moves the plastic forward and ensures an even mix of melted plastic. The machine then drives the melted plastic into a metal mold. The plastic fills the mold and results in a solid plastic part or product. Most injection molding processes employ thermoplastics that you can melt and cool multiple times, which limits material waste.

Injection Moulding: One of the most common plastic manufacturing methods, injection molding lends itself to mass production of products ranging from cell phone stands to toys. The injection molding process melts resin pellets inside the injection machine with a heated barrel. An auger moves the plastic forward and ensures an even mix of melted plastic. The machine then drives the melted plastic into a metal mold. The plastic fills the mold and results in a solid plastic part or product. Most injection molding processes employ thermoplastics that you can melt and cool multiple times, which limits material waste.

Our company have strong technical force, advanced technical equipments, complete testing means and scientific quality management.

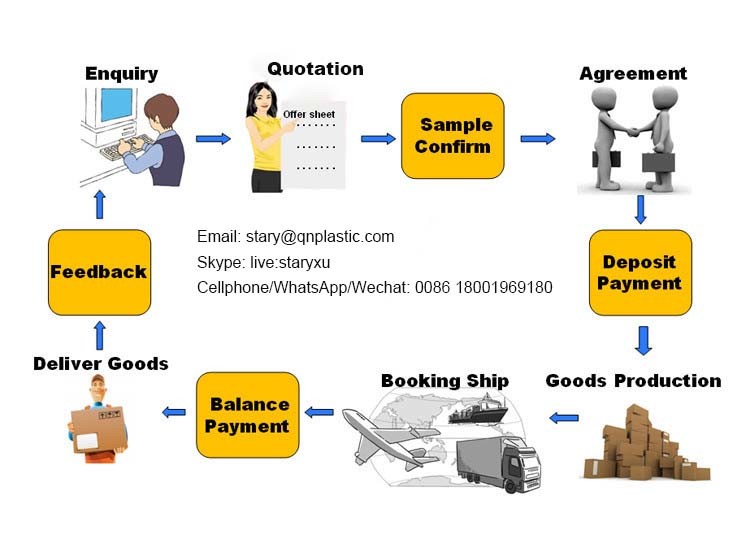

How to place an order?  Welcome to your design drawing and sample.

Welcome to your design drawing and sample.