Easy Installation Cheap Steel Structure Homes for Steel Kit Homes

| Price: |

US $ 80/Square Meter |

| Trade Terms: |

FOB,CFR,EXW |

| Min Order: |

200/Square Meter |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: |

prefabricated house-18 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Structure Type: |

Portal, Truss, Grid Structure |

| Design Load: |

Wind Speed, Snow Load, Earthquake etc |

| Steel Grade: |

Q235B Q345b |

| Strucuture Anti Rust Grade: |

St2.5 Painted, or Hot DIP Galvanized |

| Roof And Wall: |

Steel Sheetsandwich, EPS Cement Panel |

| Bracing: |

Rod Steel, Angle Steel, C/Z Purlin etc. |

| Connection: |

Bolt Connect, Weld Connect |

| Window: |

Aluminum /PVC, as Requested |

| Door: |

Aluminum /PVC, as Requested |

| Installation: |

Engineer Guide Install or Send Installation Team |

| Material: |

Steel Structure |

| Usage: |

Workshop |

| Certification: |

BV |

| Customized: |

Customized |

Product Description

1. General technical description for standard prefabricated house Technical Parameter: Technical Parameter of standard prefabricated house: (1). Wind resistance: Grade 11(wind speed≤ 120km/h) (2). Earthquake resistance: Grade 7 (3). Live load capacity of roofing: 0.6kn/m2 (4). External and internal wall heat transmission coefficient: 0.35Kcal/m2hc (5). Second Floor Load Capacity: 150 kg/m2 (6). Live load of corridor is 2.0kn/ m2 (7). Wall permitted loading: 0.6KN/ m2 (8). Ceiling Permitted live loading: 0.5 KN/m2 (9). Wall Coefficient of thermal conductivity: K=0.442W/m2k (10). Ceiling Coefficient of thermal conductivity: K=0.55W/ m2K Steel framework Main column: Fabricated by 80*80 or 100*100 or 120*120 or 150*150 Square Tube, Q235 Steel Surface working: Alkyd painting, two primary and two surface. Main triangle Beam: Fabricated by C80, C100, C120, C140 Section steel, Q235 Steel, Surface working: Alkyd painting, two primary and two surface. Wall and roof purlin: C80, C100, C120, C140 Section steel, Q235 Steel, Surface working: Galvanized Floor Ground floor will be the concrete foundation with Ceramic tiles or PVC floor leather. First floor: 18mm plywood with 2.0mm PVC floor leather for living rooms floor Ceiling 6mm Gypsum board for dry room 12mm PVC ceiling for wet room Walls Insulated Steel Sandwich Panel wall Panel width: 950mm; Thickness: 50-1200mm. Powder coated Color steel on both sides: 0.4mm/0.5mm/0.6mm Insulation: Polystyrene, Rockwool or Polyurethane Density of Rockwool: 120Kg/m3 Density of Polystyrene: 12Kg/m3, 16KG/M3 20KG/M3 Density of Polyurethane: 40Kg/m3 Door External door: Insulated with opening dimension 950*2100mm, furnished with lock, with 3 keys. Inner door: Insulated steel door. Windows Window material: PVC window with fly screen, 4mm glass. Electrical fittings option Electrical wire, 2.5mm2 for lighting system, and 4mm2 for AC units. 16A five hole universal socket. Double tube fluorescent lamp, 220V, 50-60Hz Single Switch, Honyar brand, with junction box Electrical distribution box, box+breakers+earth leakage protective device Optional Water system fittings (1). Water drain pipe, PPR pipe, dim 16-20mm, connection fittings are made of copper, life span over 10 years. Exhaust fan or air exchange hole, size 250mm*250mm made of steel or PVC (2). Sanitary ware: Western Close tool: Ceramic, with pipes and installation fittings Urinal: Ceramic, with pipes and installation fittings Wash basin: Ceramic, with post, faucet, pipes and installation fittings Shower head, Shower base, Water mixture Temporary building Characteristics: (1). Environment protective, no garbage caused (2). Doors, windows and interior partitions can be flexibly fixed (3). Beautiful appearance, different colors for the wall and roof. (4). Cost saving and transportation convenient (5). Anti-rust and normally more than 15 years using life (6). Safe and stable, can stand 8 grade earthquake. 2. Our Services: (1). Professional design and engineering team: Full solution for site camp design. We could make the design for whole camp as per your requirement. (2). Procurement and Manufacture for all material for prefabricated building. We have a professional procurement team to make sure all the materials are with good quality. And our factory operation under ISO/CE/SGS standard, to make sure the fabrication works with high technology. (3). Site management & Installation supervision, We could send our engineers to help for the installation supervision, you just need to prepare a team which know normal construction works will be OK.Qingdao Xinguangzheng steel structure Co. Ltd specialized in various of steel structure building, jointly design, manufacture, export and erection of Industrial, Commercial and residential and Agriculture uses. We exported to more than 30 countries on 6 continents with well-established experience for more than 20 years. | Basic info |

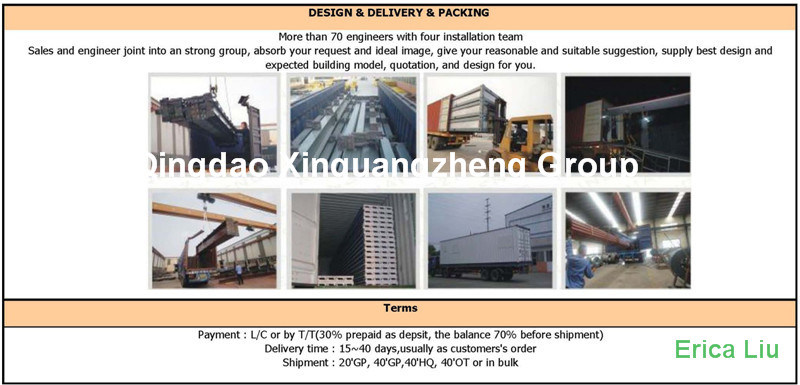

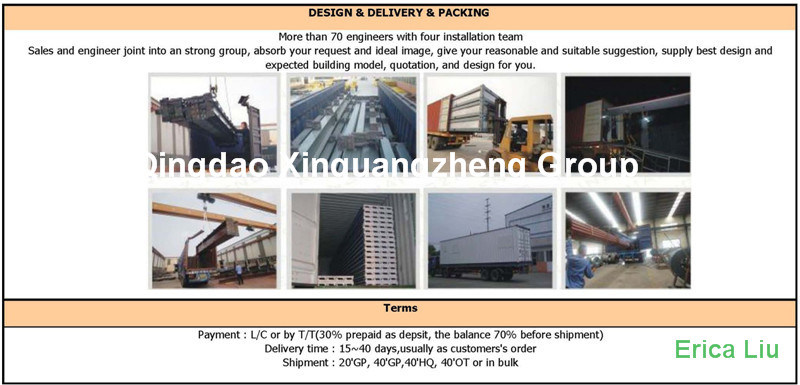

| Established time : | since 1996 |

| Factorys occupied floor area: | 40000 Square meter |

| Engineer: | more than 70 persons(keep enlarging) with 4 installaltion team |

| Capcity: | More than 3000 tons per month |

| Products scope | workshop,warehouse,prefabricated house, container house, poultry house,aircraft hanger

with full system design, manufacture, deliver, installation and after sale service. |

| Material List For Prefabricated House |

| Main Steel Frame |

| Steel column | Fabricated by Q235 or Q345 Steel, 80*80 or 100*100 or 120*120 or 150*150 Square Tube, alkyd paiting, two primary painting, two finish painting. |

| Triangular Steel structure roof | Fabricated by Q235 or Q345 Steel, C80, C100, C120, C140 Section steel, alkyd paiting, two primary painting, two finish painting. |

| Roof Purlin | Fabricated by Q235 Steel, C80, C100, C120, C140 Section steel, alkyd paiting, two primary painting, two finish painting. |

| Ordinary bolt | 4.8S, Galvanized |

| Roof and Wall |

| Roof Panel | A: Insulated Steel Sandwich Panel wall

(1) Panel width: 950mm;

(2) Thickness: 50-1200mm.

(3) Powder coated Color steel on both sides: 0.4mm/0.5mm/0.6mm

B: Insulation: Polystyrene, Rockwool, Fiber Glass or Polyurethane

(1) Density of Rockwool: 120Kg/m3

(2) Density of Polystyrene: 12Kg/m3, 16KG/M3 20KG/M3

(3) Density of Polyurethane: 40Kg/m3

(4) Density of Fiber Glass:40Kg/m3, 60Kg/m3 |

| Wall Panel | A: Insulated Steel Sandwich Panel wall

(1) Panel width: 950mm;

(2) Thickness: 50-1200mm.

(3) Powder coated Color steel on both sides: 0.4mm/0.5mm/0.6mm

B: Insulation: Polystyrene, Rockwool, Fiber Glass or Polyurethane

(1) Density of Rockwool: 120Kg/m3

(2) Density of Polystyrene: 12Kg/m3, 16KG/M3 20KG/M3

(3) Density of Polyurethane: 40Kg/m3

(4) Density of Fiber Glass:40Kg/m3, 60Kg/m3 |

| Edge Cover | 0.4mm galvanized color steel , angle Alu. |

| Fasteners & Accessoreis | Nails\glue ect |

| Ceiling&Flooring |

| Ceiling | 6mm gypsum board,with steel keel |

| Plywood | 18mm film faced plywood |

| Floor feather | 1.5mm PVC floor leather |

| Door and window |

| Door | (1) External door: Single open door. Insulated with opening dimension 950*2100mm, furnished with lock with 3keys.

(2) Inner door: Single open door. Insulated steel door. |

| Window | 4mm glass PVC window witn flying screem |

| Electrical System |

| Electric Cable | (1) Three diferent color.

(2) Lighting: 2.5m m2.

(3) Air condition: 4.0mm2.

(4) BV cable, solid core. |

| PVC Wire Channel | PVC wire channel |

| Lights | Double tube fluorescent lamp, 220V,50-60HZ |

| Switches | Single Switch, with junction box |

| Socket | 16A five hole univesal socket. |

| Power Distribution Cabinet | Box+breakers+earth leakage protective device |

| Water&Plumbing system(choose) |

| Water drain pipe | (1) PPR pipe, dim 16-20mm, connection fittings are made of copper, life span over 10 years.

(2) Exhaust fan or air exchange hole, size 250mm*250mm made of steel or PVC |

| Sanitary ware | (1) Western Close tool: ceramic, with pipes and installation fittings

(2) Urinal: ceramic, with pipes and installation fittings

(3) Wash basin: ceramic, with post, faucet, pipes and installation fittings

(4) Shower head, Shower base, Water mixture |

Plumbing System and Rain Water Drainage System as per building design

|

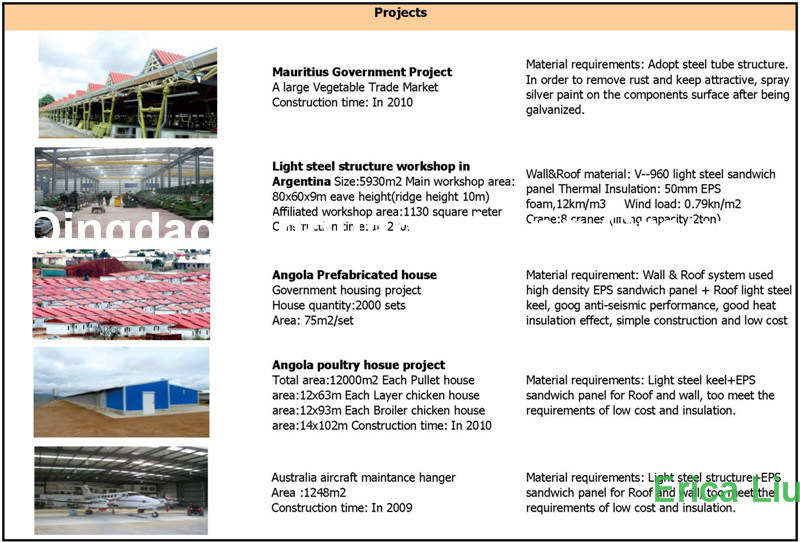

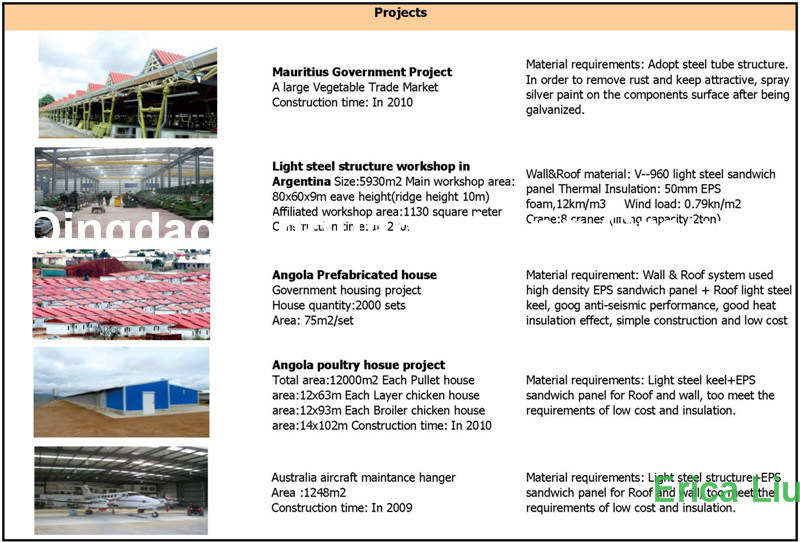

Since 1996, Qingdao Xinguangzheng Bere Steel Structure Co., Ltd. Has been specialized in designing and manufacturing steel structure workshop, steel structure warehouse, steel structure aircraft hangar, steel structure building, steel structure poultry house and prefab houses. We also passed approval of CE, BV, SGS and ISO9001 Certification. We can send our engineer to the project site overseas. Besides, We also have our own abroad guiding installation team consisting of more than 30 people. Our steel structure buildings products have been exported to Ethiopia, Tanzania, Nigeria, South Africa, Algeria, Dubai, Saudi Arabia, Thailand, Australia, France, Germany etc. Around the world.

Production Capacity

Highly precise equipment including gantry planers, automatic submergde arc welding equipment, assembling machines, slitting machines, and shot blasting machines. We have three EPS sandwich panel production line, an annual output of 300, 000 meters; Eight corrugated steel sheet production line, an annual output of 1.225 million meters; Three production line for H section steel with an annual output of 50, 000 tons; C section steel production line six, an annual output of 4, 000 tons; A Z section steel production line an annual output of 3, 000 tons. In this way, the whole system from steel structure design, manufacture, installation to after-service was established.

R&D Capacity and Quality Control

The design team at Xinguangzheng is comprised of ten professional design engineers with master's or bachelor degrees, in addition to twenty detail designers. They are able to ensure and improve our product quality through technological innovation and strict management. They use software: Auto CAD, PKPM, 3D3S, Tekla Structures(Xsteel)V12.0. etc. Our 21 QC inspectors with up to 30 years experience rigorously tracking each step of production to ensure high qualified steel structure building, steel structure workshop, steel structure warehouse, aircraft hangar and poultry house to reach our customers.

Honor & Certification

With the business principal of "credibility determines brand", we have got lots of honors: National Class-B Certificate of Professional Contracting of Steel Structure Projects; Top 10 Corporations for Professional Contracting of Building Construction in Qingdao City; Key Enterprises in Pingdu City; Trustworthy Enterprises in Shandong Province and so on. We have passed the approval of ISO: 9001: 2008, BV, SGS Certification, also we have got the qualification certification of construction enterprise: Class I Speciality Contractor for steel structure project.

Why choose us

We have rich experiences on steel structure workshop plant warehouse construction, equipments supply and installation, construction and installation of steel structure for 18 years. With high professional technical forces and completely related supporting facilities, concentrating on customers'satisfaction, we provide our customers with full sets of equipment scheme project to creat steel structure integration project.

With comprehensive advantages of light weight, industrialized manufacture, fast installation, shorter construction time, good performance of anti-quake design, fast investment recovery period, environment friendly, the steel structure has been reasonably and widely used in construction area all over the world, especially in the developed countries and regions. Our steel structure workshop, steel warehouse building, steel structure poultry house, aircraft hangar and prefab house have been exported to more than 60 countries, such as Ethiopia, Tanzania, Nigeria, South Africa, Algeria, Dubai, Saudi Arabia, Thailand, Australia, France, Germany etc. Around the world. Provided with professional equipments, skillful consulting team and completely construction scheme on steel structure integration project, you are welcomed to visit us.