Double Layer Separation Shaking Table for Sale

| Price: |

US $ 2300/Piece |

| Trade Terms: |

FOB,CIF,EXW |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T |

| Prod Model: |

6-S |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Layer: |

2 Layer |

| Application: |

Gold, Copper, Tin, Zinc, Tungsten, Tantalum, Columbium |

| Effective Separating Particle Size: |

2-0.022 |

| Deck Type: |

Coars Deck, Find Sand Deck or Slime Deck Optional |

| Testing: |

Supply |

| Flowchart: |

Supply |

| Installation: |

Supply |

| Spare Parts: |

Supply |

| Delivery Time: |

30 Days After The Down Payment |

| Type: |

Gravity Separator |

| Voltage: |

380V |

| Weight: |

1T |

| Certification: |

SGS |

| Warranty: |

1 Year |

| Color: |

Black |

| Customized: |

Customized |

| Condition: |

New |

| Material: |

Firber Glass |

| Material Feature: |

Anti Corrosion |

Product Description

Descriptions

Double deck shaking table is widely used for tungsten, tin, tantalum and niobium, gold, iron, manganese and other metals, ferrous metals, nonferrous metals, precious metals and other minerals and coal sorting.

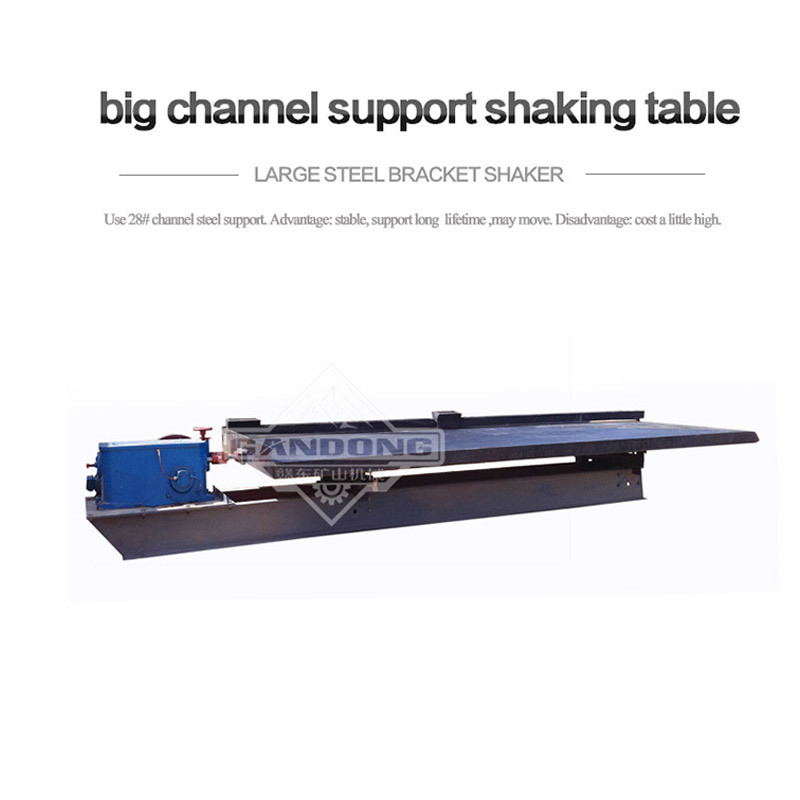

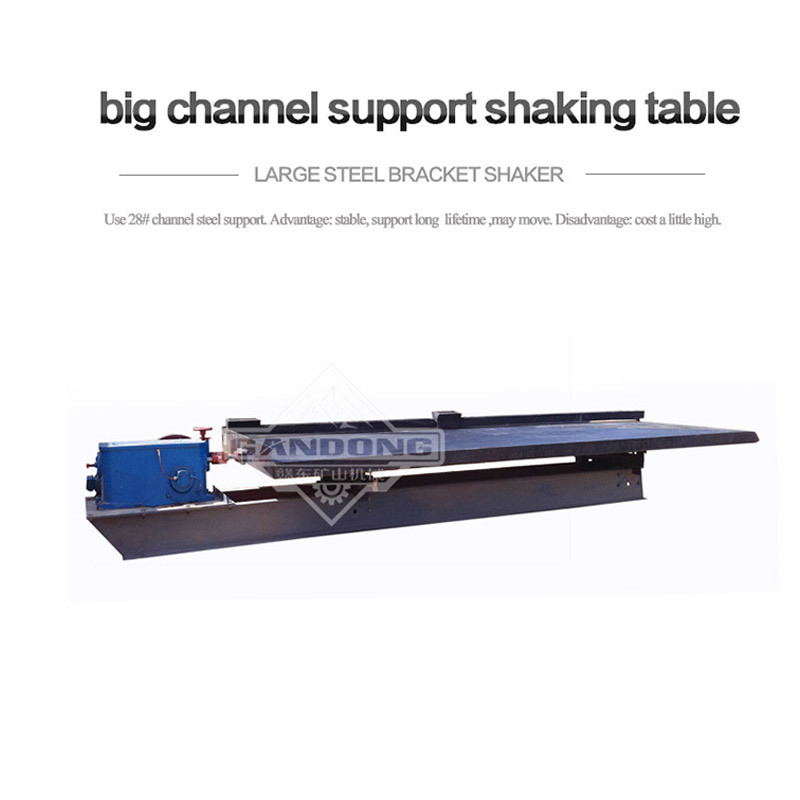

Traditional shaker covers an area of large, relatively low processing capacity,cost increases, double-shaker covers an area of inconvenience to deal with a large amount of equipment, low cost, Shaker is available in the double-sweep the election, featuring various operations, sorting coarse sand (2-0.5 mm), fine sand (0.5-0.74), sludge (0.074) different grain level, The same bed with hyperbolic rocker mechanism, the spring box in the shaker box, the crankshaft, rod, springs, rocker and so increase the size, material unchanged. The lower bed sharing a set of lower bed slope adjustment device used in shake liner support.

Technical Specifications

| Model | Unit | DL4500/1850 | DL3000/1320 |

| Bed Size | mm | 4500/1850/1560 | 3000/1320/1100 |

| Stroke | mm | 6-8 | 6-8 |

| Frequency of stroke | /min | 240-380 | 210-320 |

| Slope | o | 0-10 | 0-10 |

| Feed size | mm | 0.02-2 | 0.02-2 |

| Feed density | % | 10-30 | 10-30 |

| Water | t/h | 0.8-1.4 | 0.6-1.2 |

| Power | kw | 1.5 | 1.5 |

| Capacity | t/h | 2.5-3.5 (coarse sand) | 2.5-3 (coarse sand) |

| t/h | 1.6-2.5 (find sand) | 0.8-2.5 (find sand) |

| Overall dimensions | mm | 5600/1850/1560 | 4100/1320/1560 |

| Weight | kg | 1650 | 1550 |

we can process 6-S Single-layer deck shaking table,double-layer deck,3layer or 4layer shaking table.

FAQ:1. Q: Can I visit your factory?A: Yes. Many domestic and overseas customers visited our factory every year. 2. Q: What about the warranty of your equipment? Do you supply spare parts?A: Our warranty is one year(12 months), and we can supply spare parts also. 3. Q: Do you provide after-sales service?A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems. 4. Q: Do you provide equipment operation training?A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport. 5. Q: Do you provide producution flow chart?A: Yes. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc. 6. Q: Can you test our sample ore?A: Yes. You can send your samples to us for testing and analysis. 7. Q: Have you made the whole ore dressing lines?A: Yes. We have made many large&small scale ore dressing lines at home and abroad. For more details, please send me inquiry below, we will reply you within in 24hour,or you can call me, my cell is +86 183 7987 3189. Thanks for your time.

FAQ:1. Q: Can I visit your factory?A: Yes. Many domestic and overseas customers visited our factory every year. 2. Q: What about the warranty of your equipment? Do you supply spare parts?A: Our warranty is one year(12 months), and we can supply spare parts also. 3. Q: Do you provide after-sales service?A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems. 4. Q: Do you provide equipment operation training?A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport. 5. Q: Do you provide producution flow chart?A: Yes. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc. 6. Q: Can you test our sample ore?A: Yes. You can send your samples to us for testing and analysis. 7. Q: Have you made the whole ore dressing lines?A: Yes. We have made many large&small scale ore dressing lines at home and abroad. For more details, please send me inquiry below, we will reply you within in 24hour,or you can call me, my cell is +86 183 7987 3189. Thanks for your time.

Jiangxi Gandong Mining Equipment Machinery Manufacturer is a large beneficiation service company specialized in designing, manufacturing, installing and debugging of mining equipment as well as providing flow sheet design and course training of beneficiation, now our factory is the largest manufacturer and supplier of gravity mining equipment in China. Our factory has 12 years experience in mining equipment manufacturing, two special factories directly under the factory specialized in the manufacture of mining equipment and the manufacture of crusher and grinder. Our company covers an area of about 20, 000 square meters and with various large modernized machinery process facilities, professional mechanical and manufacturing engineers, professional mining engineers, as well as professional installation team.

Our factory has been adhering to the "honesty and realistic, quality first, technological innovation" business philosophy, successfully achieved ISO9001: 2008 Quality Management System Certificate, meanwhile cooperated with SGS and obtained SGS Audited Supplier Certificate. In addition, our factory obtained certificate of "Following Contract and Observing Credit" AA level Enterprise from Ganzhou city Administration Bureau for Industry and Commerce, and we signed an agreement of technical cooperation and product development with Jiangxi University of Science and Technology which is known as the "the cradle of nonferrous metallurgical expert", and established "East China Mining Equipment Technology Research & Development Center" and "Jiangxi Shicheng Mining Equipment Technology Research & Development Center" in our factory.

Because of excellent performance of our products and professional after-sale service, our gravity mining machine, flotation machine, classification machine, screening machine are known both at home and abroad, which gravity mining machine has a 35% market share in China. Meanwhile, we adhere to international development strategies, according to the market demand and the superiority of our products, continuously to strengthen up development of international market. Now our products have been exported to over 40 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, SouthAfrica, Zimbabwe, Sudan, Ghana, Congo, Morocco, India, Indonesia, Malaysia, Philippines, NorthKorea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide customers with one-stop service in the field of mining, including the minerals in the mineral analysis, mineral processing test, engineering design, equipment production, equipment installation, equipment debugging and of technical training etc integrated services, through the provision of our perfect services to solve all customer's problem from his investment to his return.