Categories

Categories

| Price: | US $ 950-1000/Piece |

|---|---|

| Min Order: | 1/Piece |

| Pay Type: | L/C,T/T,Western Union,Paypal |

| Prod Model: | GV-mold |

|---|---|

| Manufacturing Experience: | 25 Years |

| Spare Parts Standard: | Dme/ Hasco/ Daido/ Misumi/ Customized |

| Shaping Mode: | Injection Mould |

| Process Combination Type: | Single-Process Mode |

| Application: | Home Use |

| Installation: | Fixed |

| Items | Injection plastic mold |

| Parts materials | PC, ABS (also other material like PP, PBT, BMC, PMMA, PC+ABS, PP+TD20%, PU, PE, PVC) |

| Mold base steel | NAK80, S136, SKD61,45, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESR |

| Core and cavity steel | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh |

| Injection system | Edge gate, side gate, sub gate, direct gate, pin point gate, valve gate etc. |

| Mould standard | DME, LKM, HASCO |

| Cavity numbers | Single or multi (customized up to 32CAV) |

| Runner | Hot or cold |

| Injection machine | 50-2800T |

| Cycle time | 10-120 seconds |

| Mold of steel suppliers | Finkl, Assab, Daidao, LKM, Buderus |

| Hot runners suppliers | Synventive, Yudo, Incoe, Hasco, DME, Moldmaster, HRS, Delachaux |

| Mould life | 300,000 - 1,000,000 shots |

| Tooling lead-time | 15-40 days depends on qty & complexcity mold |

| Design software | Pro/E, UG, Catia, Solidwork, Moldflow, AutoCad |

| Mould life | 300,000-1,500,000 shots |

| Shipping packing | Wooden case or according to customer's requirements |

| Quotation Needed | 2D/3D drawing or Sample |

Company Profile:

Green Vitality Industry CO., Limited was founded in 1993, as starting from CNC processing in a small tooling building in Chang'an town, with more than 20 years experience in custom tooling and injection molding, nowadays we have become one of the global famous mold makers in manufacturing large plastic injection molds. We are full of capabilities and have great confidence in offering you professional one-stop solution of mold designing, mold making, injection molding and beyond-value service.

Factory Profile

6000 square meters mold making workshop, 8,000 square meters injection workshop.

With 160 employees, including 20 engineers, mold maker 65 people, injection molding 60 people.

Factory Capability

40 molds per month

Max. mold size 3200x2200mm, Max. mold weight 25 tons

Advantage

Good quality mold and plastic parts

Reliable service

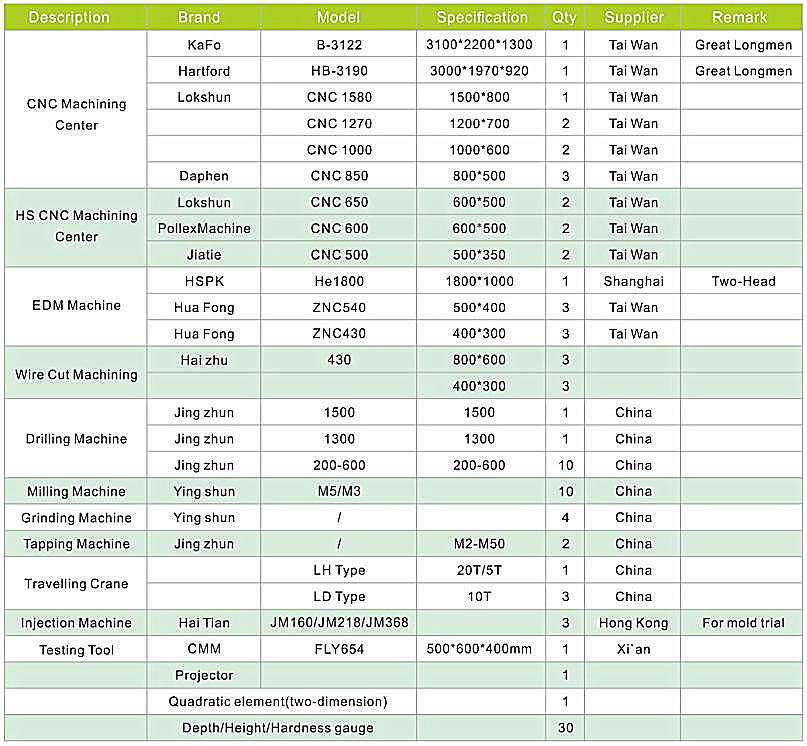

Equipment List:

Some Molds & Structure Display:

Product Display:

We serve a broad range of customers in the field of automotive industry, electronic and electrical appliances, concerning connector molding parts, auto parts, medical parts and other tooling, etc.

Design Definition Requirements:

1. Mold basic information, sample

2. Plastic components function

3. 2D drawing (weight) or 3D drawing

4. Quantity or technical requirements

5. Annually forecast or minimum order quantity

6. Surface treatment requirements, sample is better

7. Other key points

Should you have any plastic mould projects, welcome to send us the 2D/3D files and specification,

We will quote our best terms for you ASAP!

And we are ready to offer you best service at any time!