| Filtration Material 1: |

Polyester or Pet |

| Filtration Material 2: |

Acrylic |

| Filtration Material 3: |

Polyphenylene Sulfite |

| Filtration Material 4: |

Polytetrafluoroethylene or PTFE |

| Filtration Material 5: |

Polypropylene or PP |

| Filtration Material 6: |

Nomex or Aramid |

| Filtration Material 7: |

P84 |

| Filtration Material 8: |

Stainless Steel |

| Industry 1: |

Cement Plant |

| Industry 2: |

Steel Plant |

| Material: |

Non-woven |

| Medium Material: |

Synthetic Fiber |

| Type: |

Pocket Filter |

| Usage: |

Air Filter |

| Filtration Grade: |

HEPA Filter |

Product Description

Acid alkali resistance Baghouse Filter Bags for cement plant

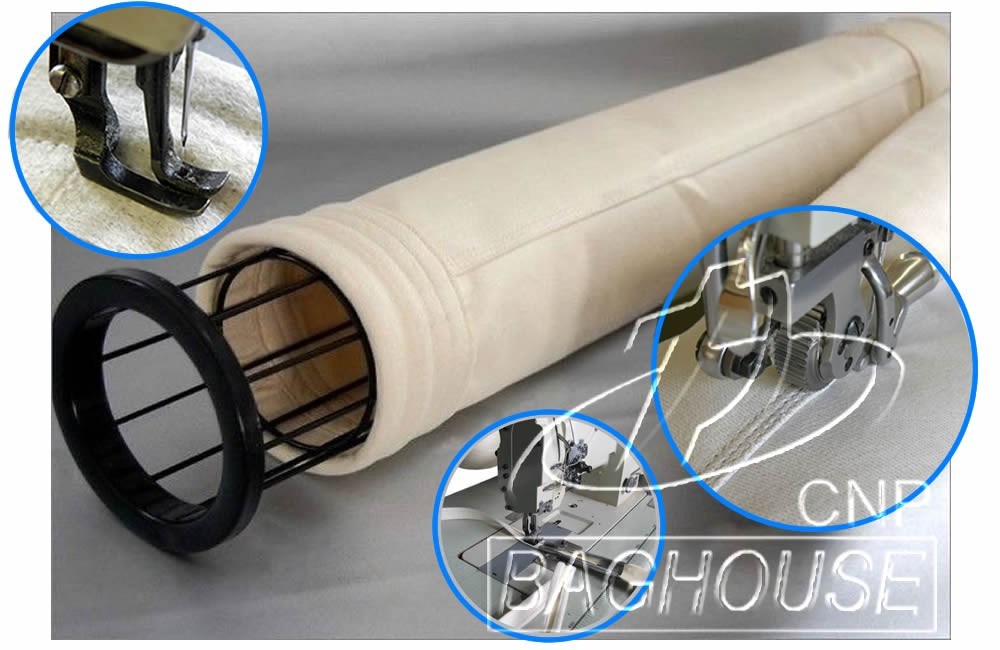

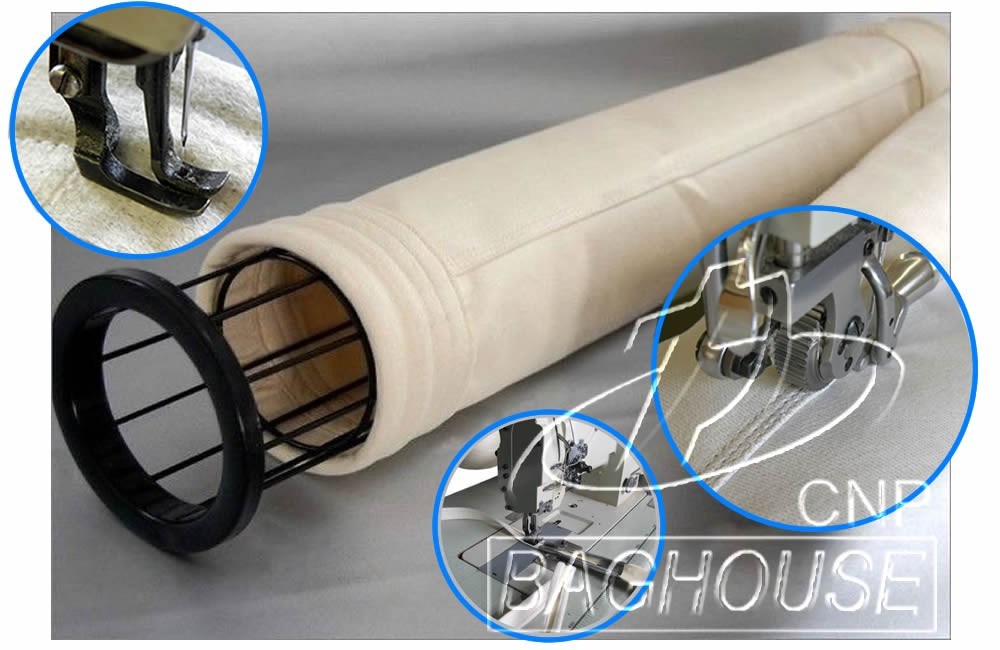

Filter bag is the core of the dust filter components. The filter bag has the strict requirements on design, filter material cutting, woven technology etc. These requirements are very important for the normal operation of the bag filter and convenient maintenance, and it is great significance to enlong the service life of the filter bag.

The filter bag sewing need attention:

Filter bag sewing material should be the same as the material of filter material. In special circumstances, we will adopt to use different filter material of sewing thread, the suture properties such as strength, heat resistance and chemical resistance should be better than the filter material sewing thread.

The filter bag stitching line:

Filter bag bag body vertical stitches must be strong, straight, and shall not be less than three line. The bag top and bottom according to different requirements with single or double needle stitching. Filter bag suture needle closely related to the filter bag material, not only to ensure the stitching rigor and suture strength not leak dust, but also shall not damage the strength of the filter material itself.

The Needle density of chemical fiber filter material filter bag should within 10 cm length (25 + / - 5) needle; Glass fiber filter material filter bag needle density can not too large. The stitching width normally for 9 ~ 12 cm. The stitches and distance on the edge of the filter material: needled felt for 2 ~ 3 mm, glass fiber filter material is 5 ~ 8 mm.

Filter bag should be according to the design requirements for inspection and repair after sewing, eliminate surface crease, dirt and grease. For PTFE coated filter bag, in addition to the needle density control and strict operating procedures, it needs to use special materials for all the pin hole repairing.

Inspection of filter bag:

Filter bag manufacture should be according to the national standards, industry standards and enterprise standards, quality supervision departments according to the number of sampling test project and the proportion. According to the number of sampling ratio is 5% ~ 20%. For higher requirements on the filter bag, As a group of sampling rate should be above 15%.

Working occasions

In industry dust collection

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

In machinery top:

Silos / Tanks

Discharging systems

Warehouse units

Mixing equipment

Homogenizing systems

Chute Bottoms

Conveyor systems

Ventilator systems

Aeration systems

Powder Coating Machinery

Bottoms for sinter basin

Filter Material Specification:

| Filter bag material | Working temperature | Chemical properties | Application 1 | Application 2 |

| Polypropylene needle felt | up to 90 degree | Good for Acid and Alkali gas | Grain | High chemical gas and less temperature |

| Polyester needle felt | Up to 130 degree | Good for Acid and nomal for Alkali | Every Dust Collection | Temperature lower than 130 degree |

| Acrylic needle felt | Up to 130 degree | Good for Acid and Alkali gas | Every Dust Collection | Chemical stronger than polyester suitalbe |

| Nomex needle felt | UP to 200 degree | Good for Acid and nomal for Alkali | Asphalt | Cement dust |

| PPS (Polyphenylene Sulphide) Needle felt | Up to 190 degree | Good for Acid and Alkali gas. Bad for Oxygen | Coal fired dust gas | Sulphur |

| P84 (Polyimide) Needle felt | Up to 240 degree | Good for Acid and Alkali gas | Incineration | Temperature lower than 240 degree |

| PTFE (Polytetrafluoroethylene) needle felt | Up to 260 degree | Good for Acid and Alkali gas | Mixed Chemical gas | Temperature lower than 260 degree |

| Glass fiber woven bulk yarn | Up to 280 degree | Good for Acid and Alkali gas | Cement kiln | Coal fired dust gas |

| Glass fiber mixed needle felt | Up to 280 degree | Nomal for Acid and Alkali gas | Acid gas | Temperature lower than 280 degree |

Company Information

CNP Co., Ltd. was founded in 2008, specializes in the field of air pollution control and bag filters. Including engineering design, planning, consulting, equipment research and development, manufacturing, sales, installation and commissioning, as well as production and services.

Based on the high starting point, CNP Co., Ltd., with a positive and upward pioneering spirit, will further create brilliancy as to technological innovation, intellectual property rights and independent brand strategy.

Our company founded in 2008, we have many years experience of industrial dust collectors export business. Our products exported to many countries around the world. In addition to the main product, the relative parts of the dust collector are also included. Such as filter bag, filter cage, centrifugal fan, discharge valve, screw conveyor and the related transport equipment, air compressor, pipe and pulse valve and so on.

Our company's services include design, production and after-sale service.

Design

Our company has strong technical force, many experienced and effective design engineers. They have got outstanding achievements in the past design that be done. The dust collectors that be designed have obtained recognition of environmental protection departments.

Produce

Our company has a variety of CNC cutting machine, cutting plate machine, bending machines and other dust collector production equipment. Production in strict accordance with the plan, drawings and standards. We set the quality inspection team for the quality control of key process. For the finished product and semi-finished products, we will strengthen management and do well of equipment maintenance work to ensure accuracy.

After-sale service:

1 Small size dust collector is easy to install, users can easy install according to the installation drawings.

2 For the installation of relatively complex medium and large size equipment, we can provide engineer overseas installation services based on customer needs.

3 Within one year after the equipment is put into operation, if any problems or parts are damaged, our company will be 100% responsible and supply the free replacement parts.

4 Provide technical support for all working life, in the course of use, if there are any problems, we will do our best to cooperate with you and service to you.

Product advantages:

1 All the dust collector of our company is designed for each working condition, which can guarantee the stable operation of the equipment. On this basis, in line with the principle of saving time and cost to design a technical and innovative products.

2 For the different nature of the dust, we will design and manufacture of special dust collector equipment, so that the maximum dust removal efficiency, guaranteed customers spend the least money, with the best products.

3 Structure is relatively simple, stable operation, less investment, easy maintenance. Widely used to eliminate dust pollution, improve the environment, recycling materials, etc...

4 Suitable for container transportation and export, can save a lot of cost than the bulk transport mode.

5 The installation is simple and easy, only simple flange connection or little welding operation is needed for field installation.