60W 80W 100W Leather Fabric Laser Cutting Machine 1.4*1.0m

| Price: |

US $ 3400-5000/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,Western Union,Paypal |

| Prod Model: |

TSHY140100 |

| Laser Type: |

CO2 |

| Application Area: |

Laser Cutting and Engraving |

| Application Material: |

Fabric, Filtering, Leather Cloth, Inflatables |

| Graphic Format Supported: |

Ai, Plt, Dxf, BMP, Dst, Dwg, Dxp |

| Power Supply: |

AC220V+-5%50Hz |

| Certification: |

Ce, ISO, FDA, CCC, BV, SGS |

| Cutting Area: |

1400mmx1000mm |

| Output Power: |

100W |

| Working Table: |

Conveyor Working Table |

| Guarantee: |

One Year Free Maintenance |

Product Description

Features:

1, It's customized for various types fabric materials'cutting for embroidery,sportswear,printing insoles,shoes,etc

2, It's good to cut any shapes without fringe and sewing automatically.

3,Converyor working table with negative pressure adsorption function can cut long size fabric continuously and to impress you, thus the fabrics still kept flatly and smoothly.

4,The following-up fume extractor system is going with laser head to save power consumption and good fume chasing effect.

5, DSP control system support online and offline data transferring.

6, Built up a data base in computer to save space room for the cutting workshop

7, Intelligent typsetting software to save material by making full use of the material

Main body:| 1). 1 × 100watts Co2 Laser tube (Installed in the machine). |

| 2). 3 × Reflecting Mirrors + 1× Focusing Lens (Installed in the machine). |

| 3). 1× 3000W Industrial Water Chiller |

| 4). 1× conveyor working table OR 1× Honeycomb table |

| 5). 1× Air Compressor + 2× Exhaust blower |

| 6). 1× USB cable (Connecting PC and Laser) |

| 7). 1× Manual (User-friendly User's Manual, Guiding video & Demo video.) |

| 8). 1× Power cable(we also stock 110V~240V power version and USA.UK.EU.AU plugs for the country all over the world) |

| 9). 1× Tool box |

Technic parameter:| Model | TSC160300LD | TSC210300LD | TSC320600 | TS160100LD | TSHY180100LD | TSHY180140 | TSZD9050 | TSZD15090 |

| Working Area | 1600x3000mm | 2100x3000mm | 3200x6000mm | 1600x1000 | 1800x1000mm | 1800x1400mm | 900x500mm | 1500x900mm |

| Laser power | 80w | 80w | 80w | 80wx2 | 80wx2 | 80w | 60W | 60W |

| Cutting Depth | Rubber 0-25mm |

| Engraving speed | 0-1000mm/s adjustable |

| Cutting speed | 0-600mm/s adjustable |

| Worktable | Fiex or conveyor or honeycomb work table |

| Resetting Positioning Accuracy | ≤±0.01mm |

| Graphic format supported | PLT/DXF/BMP/JPG/GIF/PGN/TIF,AI etc. |

| Software supported | Coreldraw, Photoshop, AutoCAD |

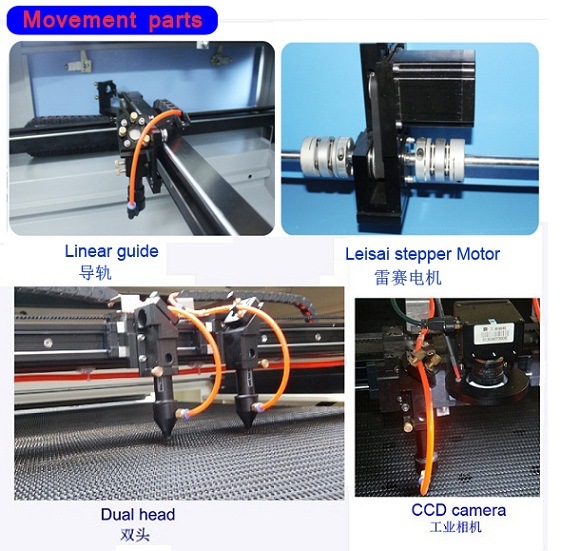

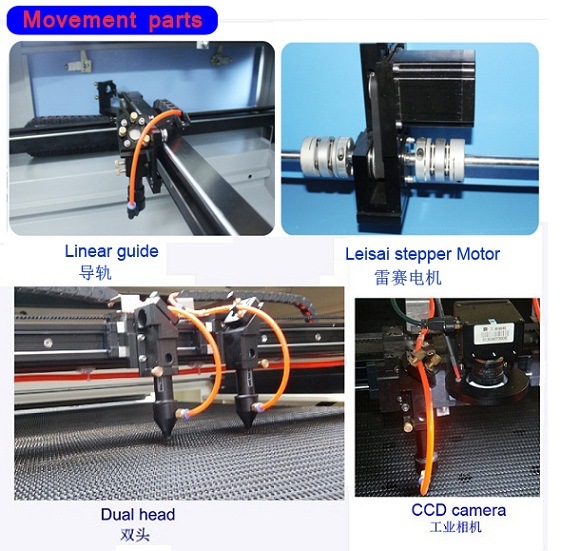

| Motor type | Stepper Motor |

| Cooling System | Water pumb/Water chiller |

| Laser tube lifetime | EFR/SPT/SP laser tube :3500h Reci laser tube:10000h |

| Power supply | 220V±10% 50HZ or 110V±10% 60HZ |

| Main configuration | 1x Laser tube |

| 1set x Reflector and lens |

| 1xWater chiller 1x air compressor 1x exhaust fan ,1x water pipe |

| 1x USB cable 1xcommunication cable 1x U disk |

| Optional Devices | Rotary device :engraving Cylinder, Pen ,Glass Cup |

| Red dot pointer, Auto Focus system |

| Auto-feeding system |

| Water chiller system |

| Consumable Parts | Laser Tube 80w/100w/130w ,reflectors and lens |

Samples

Principle:

concentrate the energy emitted from laser beam to melt the workpiece,thus cut or engrave it with high accuracy and fast speed regardless of the shape of the demo.Because of the concentration characterics,there is no deformation too.

Advantages for fabric cutting:1)No burr/fraying with laser cuttingLaser cutting is energy centered. It makes fabric edge seal automatically.No need to re-process the patterns after one-time cutting2) No distortion to the processed fabricIn the process of cutting, laser does not touch the processed fabric, only with laser beam working on the fabric3) High precisionDiameter of the laser beam can be focalized into 0.1mm (top brand lens imported from world famous company II-VI-INFRARED)Cutting is done exactly according to uploaded graphics through computer control4) High efficiency and easy operationJust upload the graphics into the cutting machine and laser will cut fabric into shapes as designed Application:

Laser cutter application: Suitable for cutting a variety of textile and industrial fabrics.

1. Industrial textile: filter cloth, bolting cloth, filter fabric, nonwoven, glass fiber, felt, synthetic fibre, fabric ducting, polypropylene (PP), polyethylene (PE), polyester (PES), polyamide (PA), cement packing, geotextile, coated fabric, sponge, insulating material and other industrial flexible materials.

2. Non-woven fabrics for health & medical: insulating material, glass fibre, polyester fibre, Microfiber, Cleanroom Wiper, Glasses cloth, Micro-fiber Wiper, non-dust cloth, clean wiper, paper diaper, etc.

3. Home furnishing fabrics: upholster, carpet, mat, floor rug, mattress, curtain, doormat, valance, wall paper, tablecloth, bed sheet, bedspread, counterpane, dust cover, sofa fabric, etc.

4. Garment fabrics: sportswear, swimwear, diving suit, exposure suit, liner, lining, adhesive interlining, wadding piece, case-hardened cotton, synthetic leather, genuine leather, etc.

5. Automotive interiors: car seat cover, car cushion, car mat, car carpet, car rug, pillowcase, air bag, auto dustproof cover, seat belt (safety belt), etc.

6. Outdoor products: polyester, nylon, PE/PVC/TPU/EVA/Oxford fabric, Oxford polyester cloth, PVC coated fabric, Tarpaulin, canvas, PVC tarpaulin, PE tarpaulins, Sail cloth, Inflatable products, tents, Inflatable toys, Inflatable castle, Inflatable boats, surf kites, fire balloon, parachute, paraglider, parasail, rubber dinghy, canopy, awning, etc.

Full services

1. service before sales: our salesman will get a full knowledge of your requirement and supply a most suitable scheme for your product. Order detailed checked and confirmed by an official procedure

2. service during production: we will send photos of machines during production.In this way customers can get updated about status

3. service before shipping: we will take photo and confirm with customers the specification of their orders to avoid the any mistakes arisen

4. service after shipping: we will seed the shipping documents to you accordingly and send a shipping advice about the ETD and ETA about the goods.

5. service after arrival: we will confirm with customers if machine is in good condition. and see if any spare parts missing .

6. service of teaching: there are some manual and video about how to use machine, if some

customers have question about it. we will have professional technician to help them to install and

teach how to use through skype ,calling, video or mail.

7. service of warranty: we offer 1 year warranty for whole machine. if any parts of our machine

is broken. we will replace it for free.

8. service in longterm : we hope every customer can use our machine easily and have a good experiences during the process of operation

If customers have any problems of machine in 2 or 3 , 5 years , they can contact us .

Guarantee&After-sale service

1, Best components, perfect technics and strictly ex- factory inspection.

2, 1 year guarantee for whole machine.

3, 24 hours (all days) technical support by call ,e-mail, skype or computer

remote control service by engineer.

4, Multi-language software, operation CD and detailed User Manual together with machine.

5, We offer free training in our factory, engineer oversea service is available if you like.

Order Notice:

Please let us know following informations:

1.What materials you want to cut ?

2.What is the mostly used thickness and what is the maximum thickness?

3. What is the MAX dimension of your materials ?

4. After cutting, what will be the metal used for? (application)

5. Are you an end user or reseller?

According to your above information,we'll recommend the most suitable machine to you.

Demo video

https://www.youtube.com/watch?v=xs_Im20mv6g carpet cutting

https://www.youtube.com/watch?v=GbkX77rZW_Q labels engraving

https://www.youtube.com/watch?v=DOUXxajO3_w insole engraving

https://www.youtube.com/watch?v=hPIgjdvG_GY fiber laser cutting metal

https://www.youtube.com/watch?v=KJ4UGkaCjkk fiber laser cutting machine

https://youtu.be/5PgXtVNajn4 large format fabric cutting

https://youtu.be/L6Rz6L3UaXY embroidery applique cutting

https://youtu.be/uy6NRT4HsrU MDF laser cutting

Taishun laser equipment Co., Ltd has been in the field of laser technology development and production for more than 20 years since the company was established, and always stand in the fore front product research and development.

Taishun company has strong Technical force and established set of perfect quality Management system, passed ISO9001: 2008 Quality Management System Certification, BV authentication, SGS and National Mandatory Product "3C" certification, which has reliable quality.

We developed 6 series of more than 10 types laser products which adopt international advanced technology. Such as, fiber laser metal cutting machine, YAG laser metal cutting machine, CO2 laser cutting and engraving machine, Fabric Flatbed laser cutting machine, Conveyor working table machine, laser marking machine and so on.

Taishun laser are good at produced medium and small laser power laser cutting machine, specially to supply one whole sets of laser processing solution scheme and related facilities for customers in plush toys, leather cutting, plush fabrics, automobile, textile, textile clothing, advertising handicrafts, electronics, medical equipment and etc. These laser equipment were widely applied in electronic circuit, auto spare parts, hardware tool, medical instrument, digital products, apparatus and instrument, optic communication component, packing and printing etc. To create a new Second-Generation small power laser cutting machine with more rapid and refinement manufacturing.