Categories

Categories

| Price: | US $ 80000-90000set |

|---|---|

| Min Order: | 1set |

| Pay Type: | T/T,Western Union |

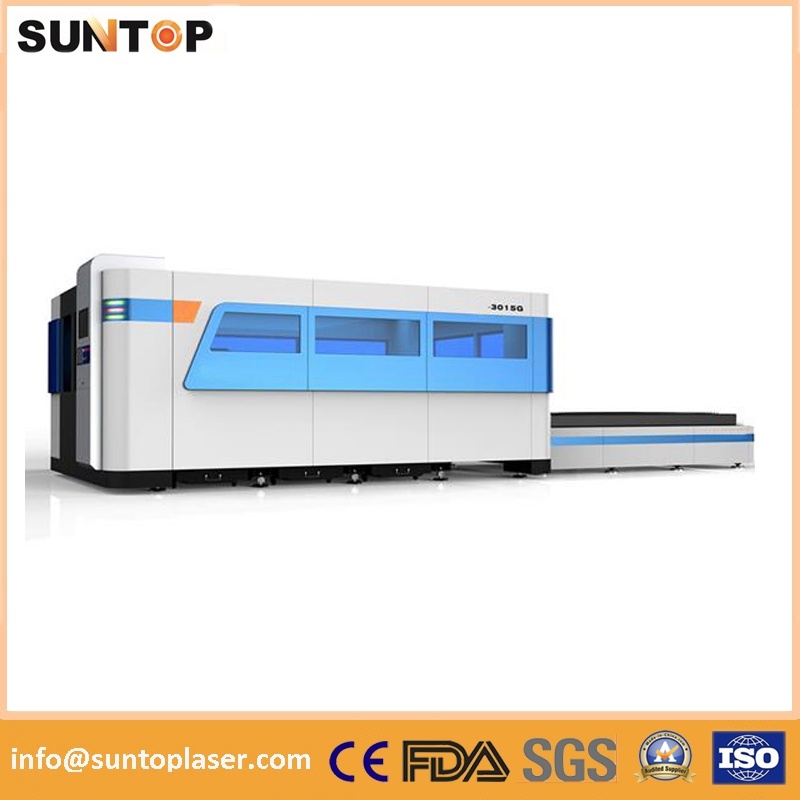

| Prod Model: | ST-FC3015-1000RD |

|---|---|

| Laser Power: | 1000W |

| Laser Type: | Fiber Laser |

| Laser Lifetime: | 100, 000 Hours |

| Gas Control Method: | Automatic by SMC Proportion Valve |

| Max. Cutting Thickness: | 10mm(Depend on The Actual Materials) |

| Effective Cutting Size: | 1500*3000mm |

| Laser Cutting Head: | Swiss Brand Raytools |

| Gantry Structure: | Aluminium Casting |

| Machine Weight: | 8000kg |

| Machine Power Supply: | 380V, 50Hz/Three Phase |

Machine gantry structure, using Japan YASKAWA servo motors drive rack and pinion feed, high precision and fast speed, dual-drive gear and rack transmission instead of the traditional ball screw transmission which makes the machine empty moving speed up to 40-50meters/Min.

Bed gantry, machine welded structure, aging treatment after annealing, roughing, finishing, can completely eliminate stress welding and machining, rigid, high precision, can be maintained long-term use not deformed( at least 20 years).

X, Y axes are imported Japan YASKAWA high precision servo motors, high speed, high torque, and high inertia, stable and durable. Ensure the machine's high speed, high precision and acceleration.

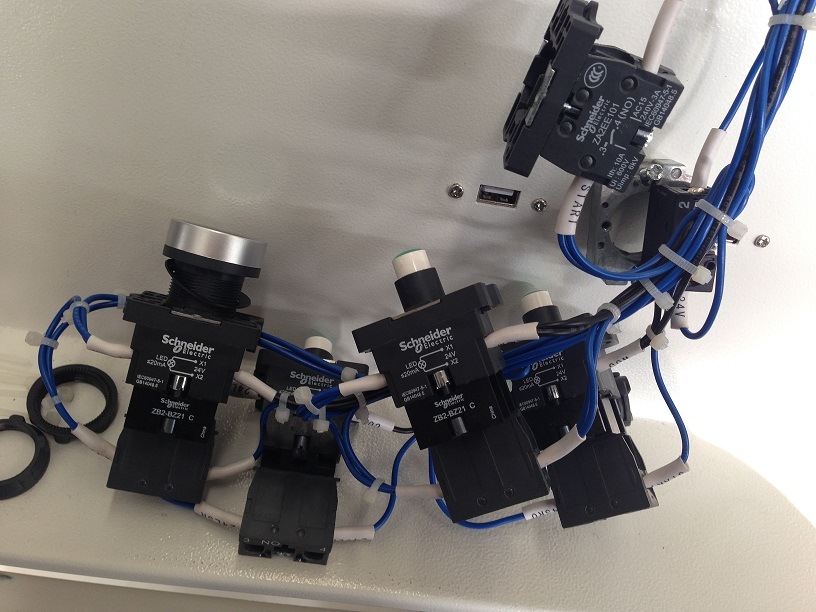

Special cutting software, integration of a number of laser cutting control specific modules, powerful, good man-machine interface, easy operation. The cutting head selection of Swiss brand high quality Ray Tools brand fiber laser cutting head as well as dedicated capacitive sensing, high precision sensor, responsive, performance of the most stable and reliable.

Control systems; Use of computer-controlled electric table translation is complete work piece cutting and so on. Cutting can be done in any graphic editor and sports plane.

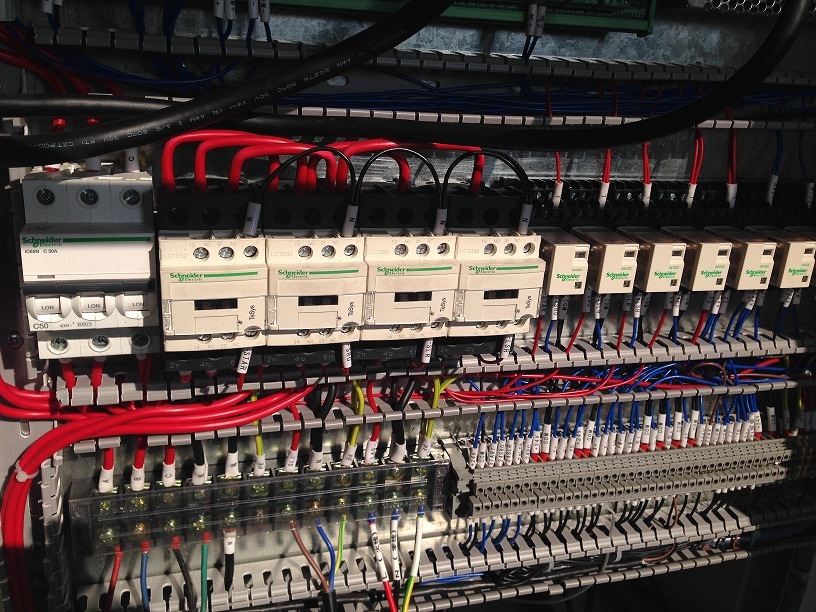

Machine main parts adopt the Europe, Japan and Taiwan famous brand, its China's price but European machine quality.

2.1 Machine tool

ST-FC3015 series bed with gantry design, machine welded structure, beams constructed of cast aluminum after annealing aging treatment, and then roughing, finishing, can completely eliminate stress welding and machining, rigidity, precision high, can be maintained long-term use at least 20 years not deformed.

Machine Beam gantry with the overall Aluminium casting parts which can reduce weight beams, to ensure good stability, high-speed operation can meet the machine.

Machine weighing 4 tons, variable analysis technique using structural dynamic design principle and finite element method designed machine base has excellent static and dynamic performance.

ST-FC3015 machine's technical parameters | |||

Floor area | About 4650 * 2520mm (excluding loading and unloading area) | ||

Allow material Maximum cutting area | 1500*3000mm | ||

Machine Gross weight | 4000KG | ||

Power supply requirements | 380V/ 50Hz | Total power | 20KW |

Environmental requirements | Temperature range: 10-35 ºC Humidity range: 40-85% | ||

Equipment moving system parameters | |||

Cutting speed, acceleration | 0-50m/min 0-3000mm/s2 | ||

Air-way speed, acceleration | 0-50m/min | ||

Positioning accuracy | <0.03mm/m | ||

Drive System | Adopt Japan YASKAWA servo motors drive | ||

Transmission | All use high precision helical rack and pinion | ||

Feedback and transport control systems | Dedicated transport and control system | ||

Ventilation system | Fixed lower ventilation | ||

Workbench Type | Rack Workbench | ||

Circuit and protection system | Standard Design | ||

| ST-FC Series Laser Cutting macine main function | ||

| No. | Function | Description |

| 1 | Height Follow-Up | Torch Move Up And Down According To Plate Height |

| 2 | Power Control | Laser Power Control According To Slope |

| 3 | Reverse Function | Reverse To Execute NC Program |

| 4 | Breakpoint Return | Return To Breakpoint After Recovery |

| 5 | Multi Piercing | Pulse, Blasting, Progress, High-Speed |

| 6 | Lead Line | Set Lead Line Parameter |

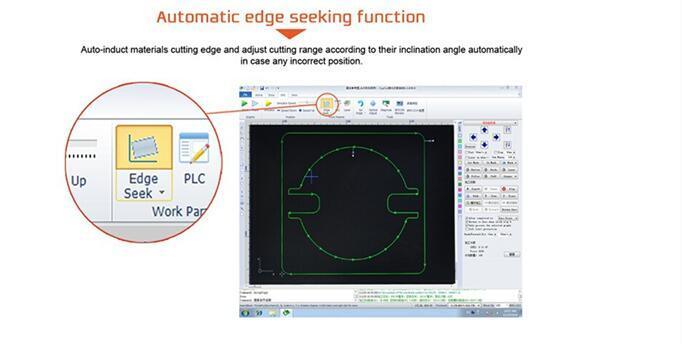

| 7 | Auto Edge-Finding | Find Cutting Piece Coordinate Automatically |

| 8 | Leapforg Function | Leapforg To Improve Cutting Efficiency |

| 9 | Common Line | Common Line To Improve Cutting Efficiency |

| 10 | Marking Function | Mark Any Shape On Plate |

| Material | Thickness (mm) | Recommend Cutting Speed(mm/min) | Max Cutting Speed(mm/min) | Power (W) | Cutting Gas | Gas Pressure (kPa) | Focus (mm) | Nozzle Model | Defocusing (mm) |

| SS | 1 | 10000 | 12000 | 700 | N2 | 8 | 0 | 1.5 | 0.7 |

| SS | 1.5 | 5000 | 5500 | 700 | N2 | 8 | 0.7 | ||

| SS | 2 | 2500 | 3000 | 700 | N2 | 9 | -1 | 1.5 | 0.7 |

| SS | 3 | 1500 | 1800 | 700 | N2 | 9 | -2 | 2 | 0.7 |

| SS | 4 | 1200 | 1400 | 700 | N2 | 9 | -2 | 2 | 0.7 |

| SS | 5 | 600 | 680 | 700 | N2 | 10 | -3 | 2 | 0.7 |

| MS | 0.5 | 9000 | 10000 | 700 | O2 | 1 | 2 | 1.2 | 0.7 |

| MS | 1 | 8000 | 9000 | 700 | O2 | 1 | 2 | 1.2 | 0.7 |

| MS | 1.5 | 6200 | 7000 | 700 | O2 | 1.4 | 2 | 1.2 | 0.7 |

| MS | 2 | 3500 | 4000 | 700 | O2 | 1.4 | 2 | 1.2 | 0.7 |

| MS | 3 | 3000 | 3600 | 700 | O2 | 1.2 | 2 | 1.2 | 0.7 |

| MS | 4 | 1800 | 2000 | 700 | O2 | 1.2 | 2 | 1.2 | 0.7 |

| MS | 5 | 1500 | 1800 | 700 | O2 | 0.6 | 2 | 1.2 | 0.7 |

| MS | 6 | 1100 | 1200 | 700 | O2 | 0.8 | 2 | 1.5 | 0.7 |

| MS | 8 | 900 | 1000 | 700 | O2 | 0.6 | 2 | 1.5 | 0.7 |

| MS | 10 | 700 | 800 | 700 | O2 | 0.7 | 2.5 | 1.5 | 0.7 |

Machine Part | Power (kW) | Power Consumption (kW/Hour) | Note |

| Laser Generator | 5.8 | <=21 | Due to the power price is different in every country, so I can only give power consumption, couldn't give total price cost |

| CNC Table | 5.8 | ||

| Cooling Unit | 5 | ||

| Extraction Filter | 4.4 |

Gas | Consumption (Minute/Bottle) | Note | Note |

O2 | 60 | Calculated based on 1mm MS Plate | Due to the gas price is different in every country, so I can only give gas consumption, couldn't give total price cost |

N2 | 15 | Calculated based on 1mm SS Plate |

Consumables | Life(Hour) | Unit Price (USD/Piece) | Total Cost (USD/Hour) | Note |

| Protective Mirror | >=240 | 43 | 0.18 | If working environment is good, then consumables' Life will be longer |

| Nozzle | >=600 | 21.4 | 0.04 | |

| Ceramic Ring | >=1500 | 108 | 0.07 | |

| Total | 0.29 USD/Hour | |||

Item | Power Consumption | Gas Consumption (USD/Hour) | Consumables | Note |

| O2 | <=21 kW/Hour | 60 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm MS Plate |

| N2 | <=21kW/Hour | 15 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm SS Plate |